Key Insights

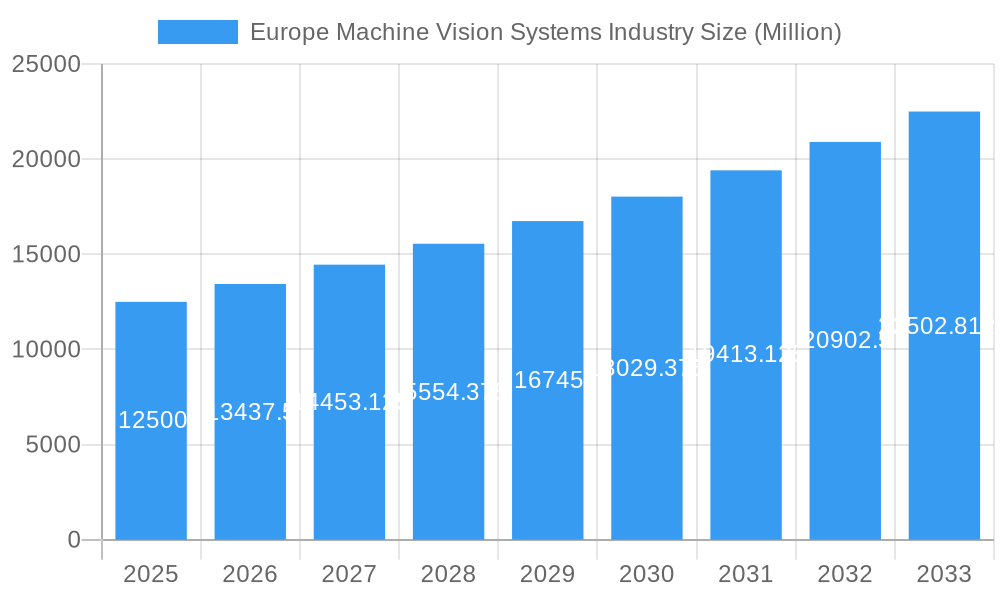

The European Machine Vision Systems market is projected to reach $14.11 billion by 2025, with a projected Compound Annual Growth Rate (CAGR) of 7% through 2033. This significant growth is driven by increasing automation and quality control demands across industries, stringent regulatory compliance, and advancements in camera technology, processing power, and AI integration. The automotive sector's adoption of ADAS and autonomous driving is a key driver, alongside the e-commerce sector's need for efficient logistics and warehousing solutions. Healthcare and pharmaceuticals are also boosting adoption through applications in diagnostics, sterile packaging inspection, and robotic surgery.

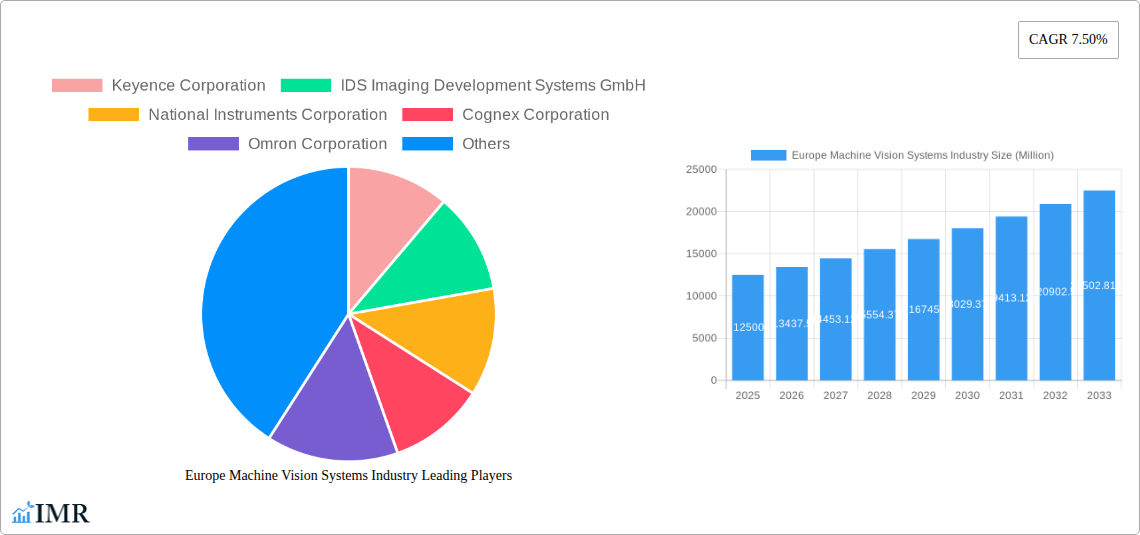

Europe Machine Vision Systems Industry Market Size (In Billion)

The market comprises core hardware components like Vision Systems, Cameras, Optics, Illumination Systems, and Frame Grabbers, supported by essential software for advanced image processing and data analysis. While PC-based systems dominate, Smart Camera solutions are gaining traction due to their integration ease and cost-effectiveness, particularly for SMEs. Leading companies like Keyence, Cognex, and Omron are innovating to meet evolving market needs. Emerging trends include deep learning and AI for enhanced object recognition and predictive maintenance, alongside the rise of 3D machine vision for complex inspection tasks. Challenges include high initial investment costs and a shortage of skilled personnel.

Europe Machine Vision Systems Industry Company Market Share

Europe Machine Vision Systems Industry Market Dynamics & Structure

The Europe Machine Vision Systems industry is characterized by a dynamic interplay of technological advancements, evolving regulatory landscapes, and increasing adoption across diverse end-user sectors. Market concentration is moderate, with a few key players holding significant shares, yet the presence of numerous specialized providers fosters healthy competition. Technological innovation remains a primary driver, fueled by advancements in AI, deep learning, and sensor technology, enabling more sophisticated and autonomous inspection capabilities. Regulatory frameworks, particularly concerning data privacy and industry standards, are increasingly influencing system design and deployment. Competitive product substitutes, while present in the form of manual inspection and less advanced automation, are rapidly being outpaced by the efficiency and accuracy of machine vision solutions. End-user demographics are shifting towards sectors demanding higher precision, speed, and quality control, such as automotive, electronics, and pharmaceuticals. Mergers and acquisitions (M&A) activity has been consistent, as larger players seek to acquire innovative technologies and expand their market reach.

- Market Concentration: Moderate, with a blend of large, established vendors and agile smaller enterprises.

- Technological Innovation Drivers: AI integration, deep learning for defect detection, advanced sensor capabilities, 5G connectivity for real-time data processing.

- Regulatory Frameworks: GDPR compliance for data handling, evolving ISO standards for machine vision system safety and performance.

- Competitive Product Substitutes: Manual inspection, traditional quality control methods, basic automation systems.

- End-User Demographics: Growing demand from high-tech manufacturing, healthcare, food & beverage, and logistics for automated quality assurance and process optimization.

- M&A Trends: Strategic acquisitions of specialized technology firms and start-ups to enhance product portfolios and market penetration.

Europe Machine Vision Systems Industry Growth Trends & Insights

The Europe Machine Vision Systems industry is poised for substantial growth, driven by an escalating demand for automation, enhanced quality control, and improved operational efficiency across a myriad of sectors. Market size evolution is projected to be robust, with the adoption rate of machine vision solutions accelerating as businesses recognize their critical role in maintaining competitiveness and meeting stringent regulatory requirements. Technological disruptions, such as the integration of artificial intelligence and deep learning, are revolutionizing inspection capabilities, allowing for the detection of increasingly subtle defects and anomalies that were previously undetectable by human inspectors. This advancement is particularly critical in industries like automotive and electronics, where precision is paramount.

Consumer behavior shifts, while indirectly influencing the machine vision market, are manifesting in increased expectations for product quality and traceability. This translates into a greater need for sophisticated inspection systems that can guarantee consistent product standards throughout the manufacturing process. The market penetration of machine vision is expanding beyond traditional manufacturing hubs into emerging industries and smaller enterprises, facilitated by the availability of more affordable and user-friendly solutions. The Compound Annual Growth Rate (CAGR) is expected to remain strong throughout the forecast period, reflecting sustained investment in smart factory initiatives and Industry 4.0 technologies.

The increasing complexity of manufactured goods and the drive for mass customization further necessitate advanced vision systems that can adapt to varied product designs and configurations with minimal reprogramming. This adaptability, coupled with the ability of machine vision to operate in harsh or hazardous environments, is broadening its applicability. Furthermore, the growing emphasis on supply chain resilience and traceability is creating new avenues for machine vision deployment in logistics and retail for tasks such as inventory management, package inspection, and anti-counterfeiting measures. The ongoing digital transformation across European economies is creating a fertile ground for the widespread integration of machine vision technologies, solidifying its position as a cornerstone of modern industrial operations.

Dominant Regions, Countries, or Segments in Europe Machine Vision Systems Industry

The Europe Machine Vision Systems industry exhibits significant growth potential, with certain regions, countries, and segments standing out as key drivers of market expansion. Germany is consistently a dominant force within the European machine vision landscape, owing to its robust manufacturing sector, particularly in automotive and industrial machinery, and its strong emphasis on technological innovation and Industry 4.0 adoption. The country's extensive industrial infrastructure, coupled with significant R&D investments, creates a fertile ground for the deployment and advancement of machine vision solutions.

Among the various components, the Hardware segment, specifically Vision Systems and Cameras, commands a substantial market share. These foundational elements are critical for capturing visual data, and advancements in resolution, speed, and intelligent processing power continue to drive their demand. The Smart Camera-based product segment is also experiencing rapid growth, offering integrated solutions that simplify deployment and reduce system complexity, appealing to a broader range of end-users.

The Automotive and Electronics and Semiconductors end-user industries are paramount in driving market growth. The automotive sector relies heavily on machine vision for critical applications such as quality inspection of components, assembly verification, defect detection, and autonomous driving system development. Similarly, the electronics industry utilizes machine vision for high-precision inspection of printed circuit boards (PCBs), semiconductor wafers, and intricate electronic components, ensuring adherence to extremely tight tolerances and defect-free production.

- Dominant Country: Germany, owing to its strong industrial base and commitment to Industry 4.0.

- Key Segments (Component): Hardware (Vision Systems, Cameras)

- Key Segments (Product): Smart Camera-based

- Dominant End-User Industries: Automotive, Electronics and Semiconductors

- Drivers for Dominance:

- Automotive: Stringent quality standards, need for high-volume production efficiency, ADAS development.

- Electronics & Semiconductors: Miniaturization trends, demand for ultra-high precision inspection, defect prevention in micro-manufacturing.

- Germany: Strong manufacturing ecosystem, government support for innovation, skilled workforce.

- Smart Cameras: Ease of integration, reduced footprint, cost-effectiveness for SMEs.

The Food and Beverage industry is another significant contributor, driven by the need for enhanced food safety, quality control, and compliance with strict regulatory mandates. Machine vision plays a crucial role in inspecting packaged goods, verifying labels, detecting contaminants, and sorting products based on quality attributes. The Healthcare and Pharmaceutical sector is also a growing market, where machine vision is employed for inspection of drug packaging, tablet quality control, surgical instrument verification, and laboratory automation, ensuring patient safety and regulatory compliance. The ongoing digitalization of these sectors and the pursuit of greater operational efficiencies are expected to sustain and accelerate the growth of machine vision adoption across Europe.

Europe Machine Vision Systems Industry Product Landscape

The Europe Machine Vision Systems industry is witnessing a surge in innovative product offerings characterized by enhanced intelligence, miniaturization, and specialized functionalities. Recent advancements include high-resolution cameras with superior low-light performance and expanded dynamic range, enabling more precise defect detection in challenging lighting conditions. AI-powered vision systems are at the forefront, offering self-learning capabilities for anomaly detection and classification, significantly reducing the need for extensive programming and sample training. Integration of advanced optics, such as telecentric lenses and specialized illumination systems (e.g., structured light, UV illumination), allows for the capture of detailed 3D information and surface defect analysis. Software platforms are becoming more intuitive, offering cloud-based analytics and real-time data processing for immediate feedback and process optimization. These products are designed for diverse applications, from the intricate inspection of semiconductor wafers and pharmaceutical packaging to the high-speed quality control of automotive components and food products.

Key Drivers, Barriers & Challenges in Europe Machine Vision Systems Industry

Key Drivers: The Europe Machine Vision Systems industry is propelled by several key drivers. The relentless pursuit of operational efficiency and cost reduction across manufacturing industries is a primary catalyst. The increasing demand for higher product quality and consistency, driven by consumer expectations and stringent regulations, further fuels adoption. Technological advancements, particularly in AI, deep learning, and sensor technology, are enabling more sophisticated and versatile applications. The ongoing digitalization of manufacturing and the widespread implementation of Industry 4.0 initiatives are creating a supportive ecosystem for machine vision integration. Furthermore, the growing need for traceability and supply chain transparency contributes to the market's upward trajectory.

Barriers & Challenges: Despite the positive outlook, several barriers and challenges exist. The initial high cost of implementation, especially for advanced systems, can be a significant hurdle for small and medium-sized enterprises (SMEs). A shortage of skilled personnel capable of designing, implementing, and maintaining complex machine vision systems poses a constraint. The integration of new vision systems with existing legacy equipment can be technically challenging and time-consuming. Evolving cybersecurity threats require robust data protection measures, adding complexity and cost. Lastly, ensuring compliance with diverse European data privacy regulations (e.g., GDPR) adds another layer of consideration for system deployment.

Emerging Opportunities in Europe Machine Vision Systems Industry

Emerging opportunities in the Europe Machine Vision Systems industry are abundant and diverse. The growing demand for advanced quality control in the burgeoning e-mobility sector, including battery inspection and electric vehicle component verification, presents a significant avenue for growth. The expansion of robotics and cobots, which increasingly rely on vision for navigation and task execution, creates integrated opportunities for machine vision solutions. The application of AI-powered vision in predictive maintenance, by analyzing equipment wear and potential failures, offers a novel revenue stream. Furthermore, the increasing adoption of machine vision in less traditional sectors like agriculture (e.g., crop monitoring, sorting) and waste management (e.g., material sorting) indicates a broadening market scope. The development of edge AI solutions, enabling real-time processing directly on devices, opens doors for faster, more efficient, and cost-effective deployments.

Growth Accelerators in the Europe Machine Vision Systems Industry Industry

Several catalysts are accelerating the growth of the Europe Machine Vision Systems industry. The continuous miniaturization and cost reduction of high-performance cameras and processors are making machine vision more accessible to a wider range of businesses. The increasing availability of open-source machine learning frameworks and specialized software tools is lowering the barrier to entry for developing advanced vision applications. Strategic partnerships between machine vision providers and robotics companies are creating integrated solutions that drive adoption in automated manufacturing and logistics. Government initiatives and funding programs supporting Industry 4.0 adoption and automation across Europe are also significant growth accelerators. Finally, the ongoing push for sustainability and resource efficiency in manufacturing encourages the implementation of vision systems for waste reduction and process optimization.

Key Players Shaping the Europe Machine Vision Systems Industry Market

- Keyence Corporation

- Cognex Corporation

- Omron Corporation

- National Instruments Corporation

- IDS Imaging Development Systems GmbH

- Basler AG

- Datalogic SpA

- Teledyne DALSA

- Perceptron Inc

- Uss Vision Inc

Notable Milestones in Europe Machine Vision Systems Industry Sector

- September 2020: Omron introduced a new FH Series Vision system, featuring the industry's first defect detection AI technology that operates without learning samples. This AI technology, designed to mimic human sensory perception and skilled inspector techniques, reliably identifies previously complex defects, thereby automating human visual inspection processes.

In-Depth Europe Machine Vision Systems Industry Market Outlook

The Europe Machine Vision Systems industry is set for sustained and robust growth, driven by a confluence of technological innovation and increasing industrial demand for automation and precision. The integration of artificial intelligence and deep learning is transforming inspection capabilities, enabling more sophisticated defect detection and predictive maintenance applications. Growth accelerators such as the expansion of Industry 4.0 initiatives, government support for digitalization, and the increasing adoption of robotics are creating a highly favorable market environment. Strategic partnerships and the development of more accessible, cost-effective solutions are expanding market penetration, especially among SMEs. The outlook suggests a continuous evolution towards smarter, more integrated, and autonomous vision systems, solidifying their indispensable role in enhancing efficiency, quality, and competitiveness across European industries.

Europe Machine Vision Systems Industry Segmentation

-

1. Component

-

1.1. Hardware

- 1.1.1. Vision Systems

- 1.1.2. Cameras

- 1.1.3. Optics and Illumination Systems

- 1.1.4. Frame Grabber

- 1.1.5. Other Types of Hardware

- 1.2. Software

-

1.1. Hardware

-

2. Product

- 2.1. PC-based

- 2.2. Smart Camera-based

-

3. End-User Industry

- 3.1. Food and Beverage

- 3.2. Healthcare and Pharmaceutical

- 3.3. Logistic and Retail

- 3.4. Automotive

- 3.5. Electronics and Semiconductors

- 3.6. Other End-user Industries

Europe Machine Vision Systems Industry Segmentation By Geography

-

1. Europe

- 1.1. United Kingdom

- 1.2. Germany

- 1.3. France

- 1.4. Italy

- 1.5. Spain

- 1.6. Netherlands

- 1.7. Belgium

- 1.8. Sweden

- 1.9. Norway

- 1.10. Poland

- 1.11. Denmark

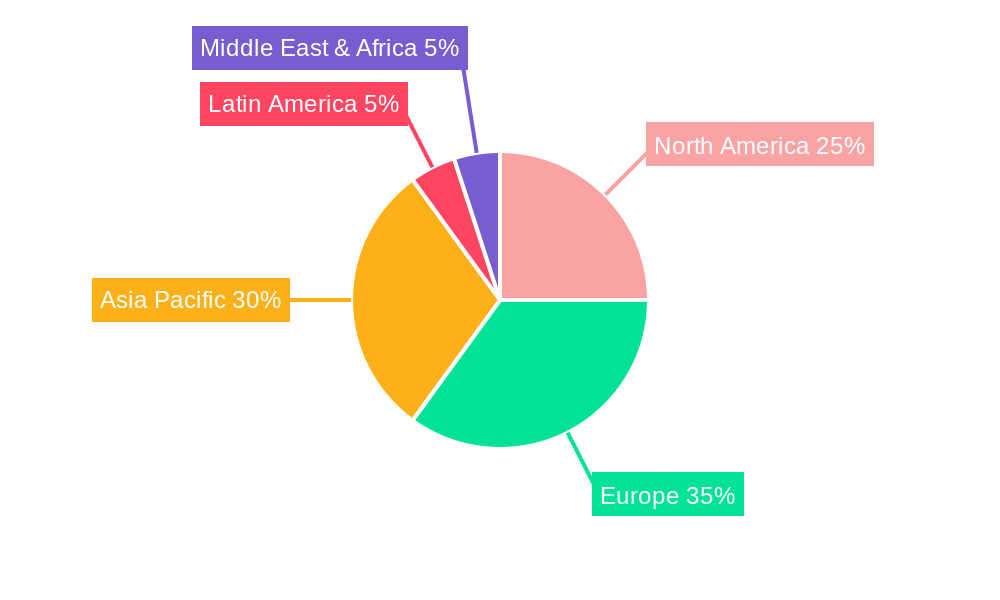

Europe Machine Vision Systems Industry Regional Market Share

Geographic Coverage of Europe Machine Vision Systems Industry

Europe Machine Vision Systems Industry REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 7% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. Increasing Need for Quality Inspection and Automation; Rising Demand for Accurate Defect Detection

- 3.3. Market Restrains

- 3.3.1. Scarcity of Flexible Machine Vision Solutions

- 3.4. Market Trends

- 3.4.1. Automotive Industry to Witness Significant Growth

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Europe Machine Vision Systems Industry Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Component

- 5.1.1. Hardware

- 5.1.1.1. Vision Systems

- 5.1.1.2. Cameras

- 5.1.1.3. Optics and Illumination Systems

- 5.1.1.4. Frame Grabber

- 5.1.1.5. Other Types of Hardware

- 5.1.2. Software

- 5.1.1. Hardware

- 5.2. Market Analysis, Insights and Forecast - by Product

- 5.2.1. PC-based

- 5.2.2. Smart Camera-based

- 5.3. Market Analysis, Insights and Forecast - by End-User Industry

- 5.3.1. Food and Beverage

- 5.3.2. Healthcare and Pharmaceutical

- 5.3.3. Logistic and Retail

- 5.3.4. Automotive

- 5.3.5. Electronics and Semiconductors

- 5.3.6. Other End-user Industries

- 5.4. Market Analysis, Insights and Forecast - by Region

- 5.4.1. Europe

- 5.1. Market Analysis, Insights and Forecast - by Component

- 6. Competitive Analysis

- 6.1. Market Share Analysis 2025

- 6.2. Company Profiles

- 6.2.1 Keyence Corporation

- 6.2.1.1. Overview

- 6.2.1.2. Products

- 6.2.1.3. SWOT Analysis

- 6.2.1.4. Recent Developments

- 6.2.1.5. Financials (Based on Availability)

- 6.2.2 IDS Imaging Development Systems GmbH

- 6.2.2.1. Overview

- 6.2.2.2. Products

- 6.2.2.3. SWOT Analysis

- 6.2.2.4. Recent Developments

- 6.2.2.5. Financials (Based on Availability)

- 6.2.3 National Instruments Corporation

- 6.2.3.1. Overview

- 6.2.3.2. Products

- 6.2.3.3. SWOT Analysis

- 6.2.3.4. Recent Developments

- 6.2.3.5. Financials (Based on Availability)

- 6.2.4 Cognex Corporation

- 6.2.4.1. Overview

- 6.2.4.2. Products

- 6.2.4.3. SWOT Analysis

- 6.2.4.4. Recent Developments

- 6.2.4.5. Financials (Based on Availability)

- 6.2.5 Omron Corporation

- 6.2.5.1. Overview

- 6.2.5.2. Products

- 6.2.5.3. SWOT Analysis

- 6.2.5.4. Recent Developments

- 6.2.5.5. Financials (Based on Availability)

- 6.2.6 Uss Vision Inc

- 6.2.6.1. Overview

- 6.2.6.2. Products

- 6.2.6.3. SWOT Analysis

- 6.2.6.4. Recent Developments

- 6.2.6.5. Financials (Based on Availability)

- 6.2.7 Perceptron Inc

- 6.2.7.1. Overview

- 6.2.7.2. Products

- 6.2.7.3. SWOT Analysis

- 6.2.7.4. Recent Developments

- 6.2.7.5. Financials (Based on Availability)

- 6.2.8 Teledyne DALSA

- 6.2.8.1. Overview

- 6.2.8.2. Products

- 6.2.8.3. SWOT Analysis

- 6.2.8.4. Recent Developments

- 6.2.8.5. Financials (Based on Availability)

- 6.2.9 Datalogic SpA

- 6.2.9.1. Overview

- 6.2.9.2. Products

- 6.2.9.3. SWOT Analysis

- 6.2.9.4. Recent Developments

- 6.2.9.5. Financials (Based on Availability)

- 6.2.10 Basler AG

- 6.2.10.1. Overview

- 6.2.10.2. Products

- 6.2.10.3. SWOT Analysis

- 6.2.10.4. Recent Developments

- 6.2.10.5. Financials (Based on Availability)

- 6.2.1 Keyence Corporation

List of Figures

- Figure 1: Europe Machine Vision Systems Industry Revenue Breakdown (billion, %) by Product 2025 & 2033

- Figure 2: Europe Machine Vision Systems Industry Share (%) by Company 2025

List of Tables

- Table 1: Europe Machine Vision Systems Industry Revenue billion Forecast, by Component 2020 & 2033

- Table 2: Europe Machine Vision Systems Industry Volume K Unit Forecast, by Component 2020 & 2033

- Table 3: Europe Machine Vision Systems Industry Revenue billion Forecast, by Product 2020 & 2033

- Table 4: Europe Machine Vision Systems Industry Volume K Unit Forecast, by Product 2020 & 2033

- Table 5: Europe Machine Vision Systems Industry Revenue billion Forecast, by End-User Industry 2020 & 2033

- Table 6: Europe Machine Vision Systems Industry Volume K Unit Forecast, by End-User Industry 2020 & 2033

- Table 7: Europe Machine Vision Systems Industry Revenue billion Forecast, by Region 2020 & 2033

- Table 8: Europe Machine Vision Systems Industry Volume K Unit Forecast, by Region 2020 & 2033

- Table 9: Europe Machine Vision Systems Industry Revenue billion Forecast, by Component 2020 & 2033

- Table 10: Europe Machine Vision Systems Industry Volume K Unit Forecast, by Component 2020 & 2033

- Table 11: Europe Machine Vision Systems Industry Revenue billion Forecast, by Product 2020 & 2033

- Table 12: Europe Machine Vision Systems Industry Volume K Unit Forecast, by Product 2020 & 2033

- Table 13: Europe Machine Vision Systems Industry Revenue billion Forecast, by End-User Industry 2020 & 2033

- Table 14: Europe Machine Vision Systems Industry Volume K Unit Forecast, by End-User Industry 2020 & 2033

- Table 15: Europe Machine Vision Systems Industry Revenue billion Forecast, by Country 2020 & 2033

- Table 16: Europe Machine Vision Systems Industry Volume K Unit Forecast, by Country 2020 & 2033

- Table 17: United Kingdom Europe Machine Vision Systems Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 18: United Kingdom Europe Machine Vision Systems Industry Volume (K Unit) Forecast, by Application 2020 & 2033

- Table 19: Germany Europe Machine Vision Systems Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 20: Germany Europe Machine Vision Systems Industry Volume (K Unit) Forecast, by Application 2020 & 2033

- Table 21: France Europe Machine Vision Systems Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 22: France Europe Machine Vision Systems Industry Volume (K Unit) Forecast, by Application 2020 & 2033

- Table 23: Italy Europe Machine Vision Systems Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 24: Italy Europe Machine Vision Systems Industry Volume (K Unit) Forecast, by Application 2020 & 2033

- Table 25: Spain Europe Machine Vision Systems Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 26: Spain Europe Machine Vision Systems Industry Volume (K Unit) Forecast, by Application 2020 & 2033

- Table 27: Netherlands Europe Machine Vision Systems Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 28: Netherlands Europe Machine Vision Systems Industry Volume (K Unit) Forecast, by Application 2020 & 2033

- Table 29: Belgium Europe Machine Vision Systems Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 30: Belgium Europe Machine Vision Systems Industry Volume (K Unit) Forecast, by Application 2020 & 2033

- Table 31: Sweden Europe Machine Vision Systems Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 32: Sweden Europe Machine Vision Systems Industry Volume (K Unit) Forecast, by Application 2020 & 2033

- Table 33: Norway Europe Machine Vision Systems Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 34: Norway Europe Machine Vision Systems Industry Volume (K Unit) Forecast, by Application 2020 & 2033

- Table 35: Poland Europe Machine Vision Systems Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 36: Poland Europe Machine Vision Systems Industry Volume (K Unit) Forecast, by Application 2020 & 2033

- Table 37: Denmark Europe Machine Vision Systems Industry Revenue (billion) Forecast, by Application 2020 & 2033

- Table 38: Denmark Europe Machine Vision Systems Industry Volume (K Unit) Forecast, by Application 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Europe Machine Vision Systems Industry?

The projected CAGR is approximately 7%.

2. Which companies are prominent players in the Europe Machine Vision Systems Industry?

Key companies in the market include Keyence Corporation, IDS Imaging Development Systems GmbH, National Instruments Corporation, Cognex Corporation, Omron Corporation, Uss Vision Inc, Perceptron Inc, Teledyne DALSA, Datalogic SpA, Basler AG.

3. What are the main segments of the Europe Machine Vision Systems Industry?

The market segments include Component, Product, End-User Industry.

4. Can you provide details about the market size?

The market size is estimated to be USD 14.11 billion as of 2022.

5. What are some drivers contributing to market growth?

Increasing Need for Quality Inspection and Automation; Rising Demand for Accurate Defect Detection.

6. What are the notable trends driving market growth?

Automotive Industry to Witness Significant Growth.

7. Are there any restraints impacting market growth?

Scarcity of Flexible Machine Vision Solutions.

8. Can you provide examples of recent developments in the market?

September 2020 - Omron introduced a new FH Series Vision system, which includes the industry's first defect detection AI technology, which detects defects without learning samples. The artificial intelligence technology, which attempts to simulate sensibility and skilled inspector techniques, reliably detects previously complex defects, automating human vision-based visual inspection.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4750, USD 4950, and USD 6800 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in billion and volume, measured in K Unit.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Europe Machine Vision Systems Industry," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Europe Machine Vision Systems Industry report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Europe Machine Vision Systems Industry?

To stay informed about further developments, trends, and reports in the Europe Machine Vision Systems Industry, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

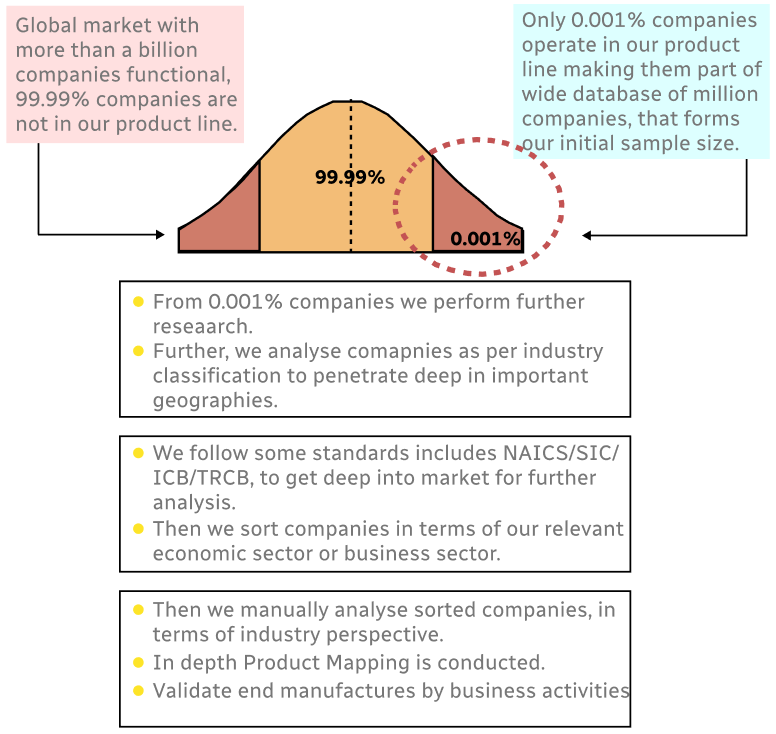

Step 1 - Identification of Relevant Samples Size from Population Database

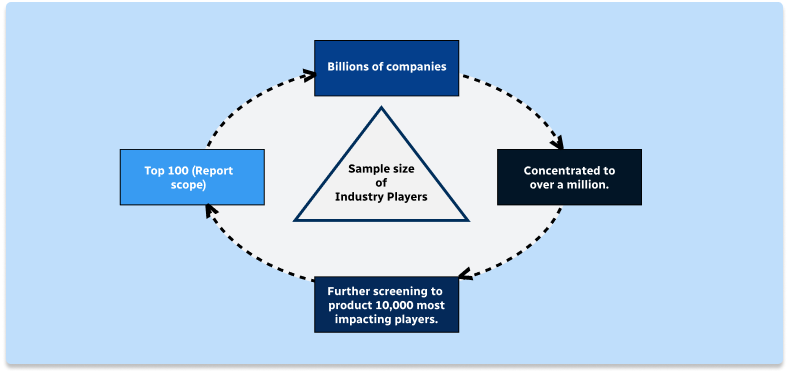

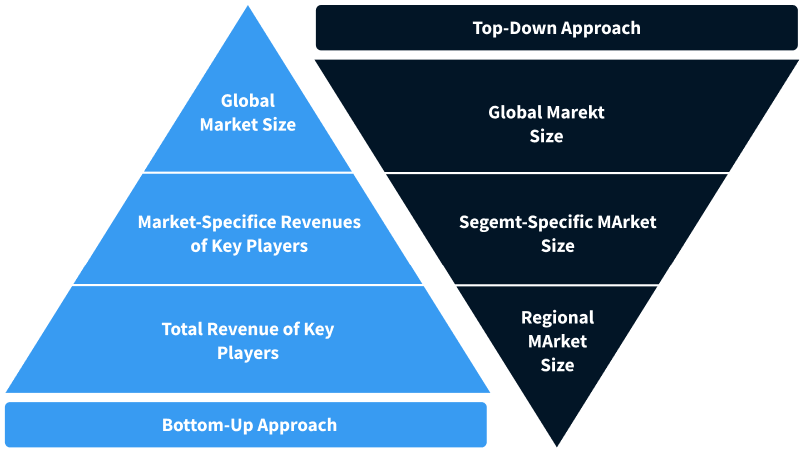

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

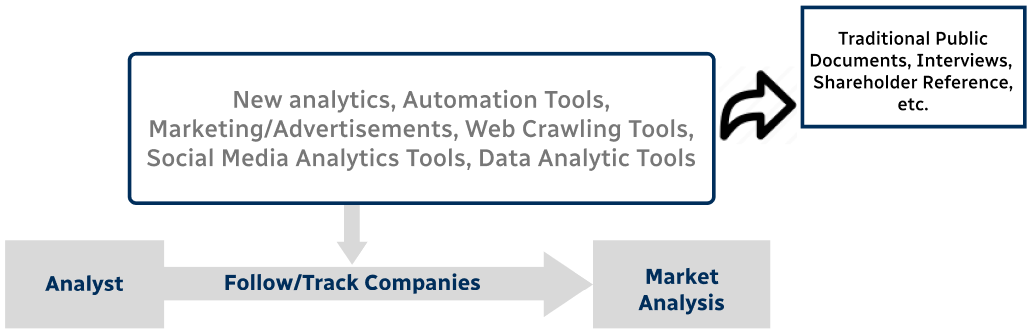

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence