Key Insights

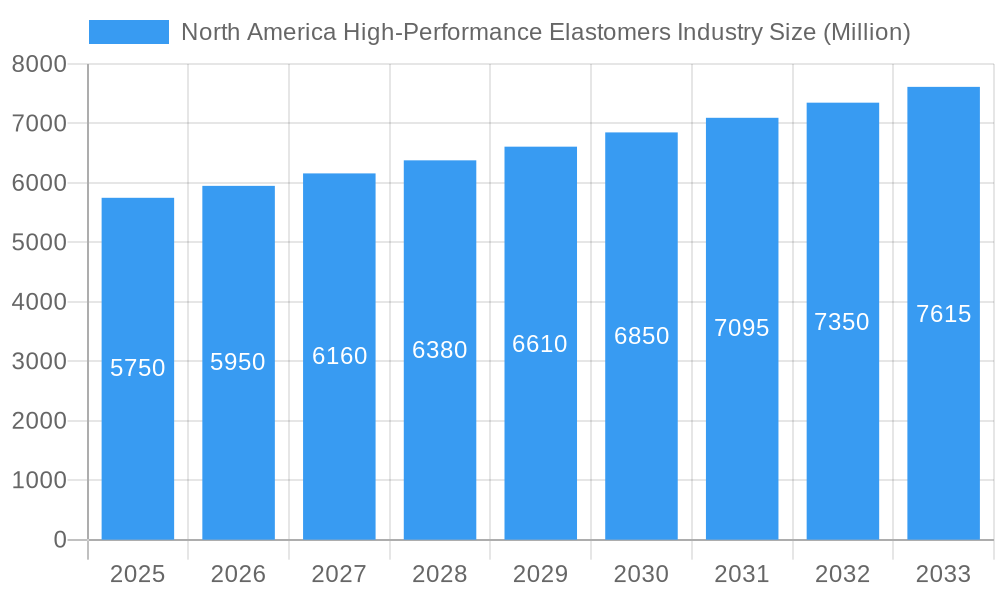

The North American High-Performance Elastomers market is poised for significant expansion, projected to grow at a Compound Annual Growth Rate (CAGR) exceeding 3.50% throughout the forecast period of 2025-2033. This robust growth, building upon a strong historical performance from 2019-2024, is driven by a confluence of factors, notably the escalating demand from the automotive & transportation sector for lightweight, durable, and fuel-efficient components. Innovations in material science are enabling the development of advanced elastomers that offer superior resistance to extreme temperatures, chemicals, and mechanical stress, making them indispensable in this sector. Furthermore, the burgeoning building & construction industry's focus on energy efficiency and sustainable materials is fueling demand for high-performance sealants and coatings. The medical industry also presents a substantial growth avenue, driven by the need for biocompatible and sterile elastomer solutions for devices and drug delivery systems. Emerging applications in consumer electronics and household appliances, where enhanced durability and design flexibility are paramount, are further contributing to the market's upward trajectory.

North America High-Performance Elastomers Industry Market Size (In Billion)

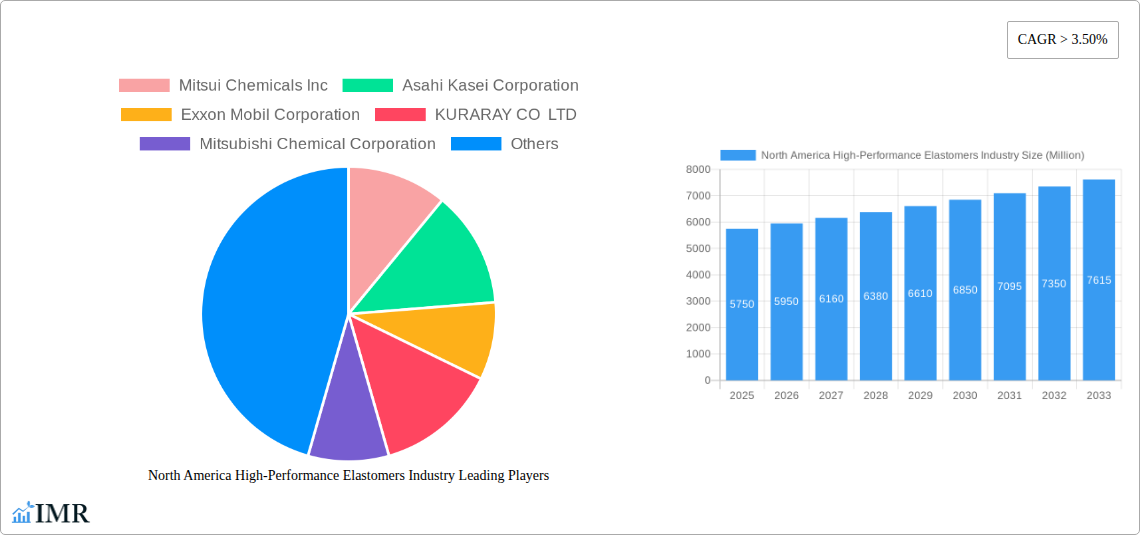

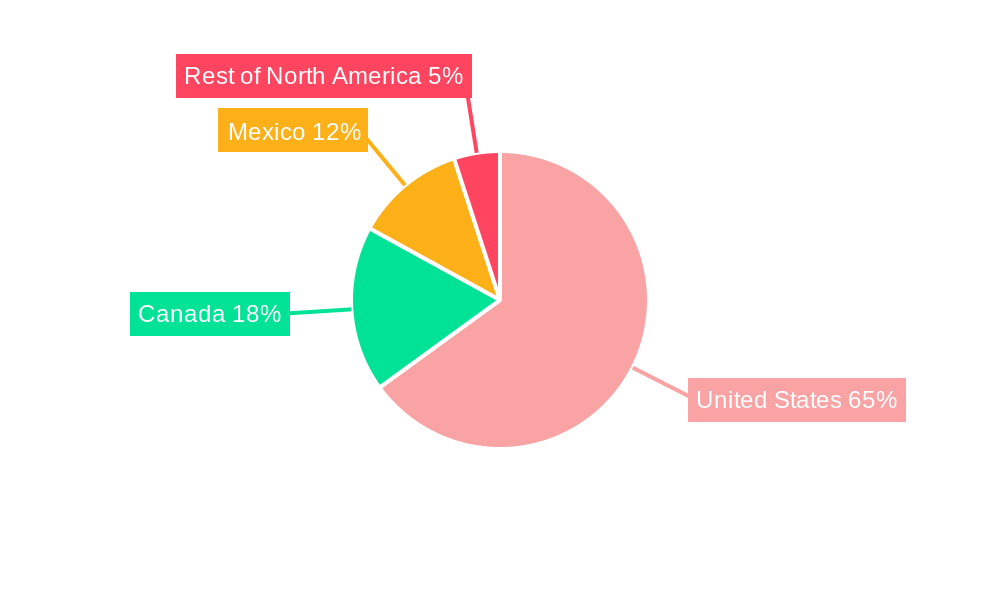

The market's dynamism is further shaped by key trends such as the increasing adoption of thermoplastic elastomers (TPEs) due to their recyclability and ease of processing, offering a sustainable alternative to traditional thermoset rubbers. Specifically, Thermoplastic Olefins (TPE-O) and Styrenic Block Copolymers (TPE-S) are gaining traction across various applications. However, the market faces certain restraints, including fluctuating raw material prices, particularly for petroleum-derived feedstocks, which can impact profitability and pricing strategies. Intense competition among established players like Mitsui Chemicals Inc., Exxon Mobil Corporation, and BASF SE, coupled with the emergence of new entrants, necessitates continuous innovation and cost optimization. The geographical landscape of North America is characterized by a dominant United States market, followed by Canada and Mexico, with the "Rest of North America" segment representing emerging opportunities. Strategic collaborations and acquisitions are expected to play a crucial role in market consolidation and expansion, as companies strive to enhance their product portfolios and geographical reach in this competitive and evolving industry.

North America High-Performance Elastomers Industry Company Market Share

This comprehensive report delivers an in-depth analysis of the North America High-Performance Elastomers Industry, encompassing market dynamics, growth trends, regional dominance, product landscape, key drivers, challenges, opportunities, and the strategic imperatives of leading players. With a study period spanning from 2019 to 2033, the report provides critical insights for industry stakeholders, investors, and decision-makers navigating this dynamic sector.

North America High-Performance Elastomers Industry Market Dynamics & Structure

The North America High-Performance Elastomers market is characterized by a moderately concentrated structure, with a significant presence of global chemical giants. Technological innovation is a primary driver, fueled by increasing demand for lightweight, durable, and sustainable materials across various applications, particularly in the automotive and construction sectors. Regulatory frameworks, while evolving to promote environmental sustainability and safety, present both opportunities for innovation and potential compliance challenges. Competitive product substitutes, such as traditional thermoset elastomers and advanced composites, are present, but high-performance thermoplastics offer distinct advantages in processing and recyclability. End-user demographics are shifting towards a greater preference for customized solutions and eco-friendly materials. Mergers and acquisitions (M&A) trends indicate a strategic consolidation of market share and the acquisition of specialized technologies. For instance, recent M&A activities have focused on acquiring niche players with expertise in advanced compounding and sustainable elastomer solutions. The market is projected to witness substantial M&A deal volumes, with an estimated xx deals in the forecast period, driven by the pursuit of vertical integration and expanded product portfolios.

- Market Concentration: Moderately concentrated, dominated by a mix of multinational corporations and specialized manufacturers.

- Technological Innovation Drivers: Demand for enhanced material properties (e.g., thermal resistance, chemical resistance, flexibility), lightweighting initiatives, and sustainability trends.

- Regulatory Frameworks: Growing emphasis on REACH compliance, environmental certifications, and recyclability mandates.

- Competitive Product Substitutes: Thermoset rubbers, silicones, advanced composites, and other engineered plastics.

- End-User Demographics: Increasing demand from automotive, healthcare, and consumer goods sectors, with a growing preference for bio-based and recyclable materials.

- M&A Trends: Strategic acquisitions for technology enhancement, market penetration, and product portfolio expansion. Expected M&A deal volume in forecast period: xx.

North America High-Performance Elastomers Industry Growth Trends & Insights

The North America High-Performance Elastomers market is poised for robust growth, driven by several converging factors. The market size, estimated at $XX,XXX million units in the base year 2025, is projected to expand at a Compound Annual Growth Rate (CAGR) of xx% during the forecast period (2025–2033). This expansion is fueled by the increasing adoption of high-performance elastomers in critical sectors like automotive and transportation, where they are integral to improving fuel efficiency, safety, and passenger comfort through applications such as seals, hoses, and interior components. The building and construction industry is another significant contributor, leveraging these materials for durable roofing membranes, window seals, and expansion joints. Furthermore, the growing demand for advanced medical devices, requiring biocompatible and sterilizable materials, is opening new avenues for thermoplastic elastomers (TPEs). Technological disruptions, including advancements in polymerization techniques and compounding technologies, are leading to the development of elastomers with superior performance characteristics, such as enhanced durability, temperature resistance, and chemical inertness. Consumer behavior shifts towards sustainable and eco-friendly products are also playing a crucial role, pushing manufacturers to develop bio-based and recyclable high-performance elastomers. The market penetration of specialized elastomers is expected to rise significantly, particularly for Thermoplastic Polyurethane (TPU) and Elastomeric Alloys (TPE-V or TPV), owing to their versatile properties and processing advantages. The historical growth from 2019 to 2024 averaged xx% annually, setting a strong foundation for future expansion. Emerging applications in wearable technology and advanced packaging further contribute to this positive outlook, showcasing the adaptability and evolving relevance of high-performance elastomers in addressing modern industrial and consumer needs. The continuous innovation in material science is unlocking new possibilities, enabling the development of tailor-made solutions for complex engineering challenges, thus solidifying the growth trajectory of this vital industry.

Dominant Regions, Countries, or Segments in North America High-Performance Elastomers Industry

The United States stands as the dominant region within the North America High-Performance Elastomers industry, commanding a significant market share estimated at xx% in the base year 2025. This dominance is attributed to a confluence of factors, including a robust manufacturing base, substantial investments in research and development, and a strong demand from key end-use industries such as automotive, aerospace, and healthcare. The country's advanced technological infrastructure and a supportive regulatory environment for innovation further bolster its leading position.

Among the product types, Styrenic Block Copolymer (TPE-S) and Thermoplastic Polyurethane (TPU) are key growth drivers. TPE-S, known for its excellent elasticity and processing flexibility, finds widespread application in footwear, adhesives, and consumer goods. The estimated market volume for TPE-S in 2025 is $X,XXX million units. TPU, on the other hand, excels in applications demanding high abrasion resistance, toughness, and flexibility, making it a preferred choice for automotive parts, industrial components, and medical devices. The market volume for TPU in 2025 is projected at $X,XXX million units.

In terms of applications, the Automotive & Transportation segment is the largest contributor to market growth. The ongoing drive towards lightweighting, electrification of vehicles, and enhanced safety features necessitates the use of high-performance elastomers for seals, gaskets, interior components, and under-the-hood applications. The estimated market size for automotive applications in 2025 is $X,XXX million units. Building & Construction is another significant segment, driven by the demand for durable and weather-resistant materials for roofing, insulation, and sealing solutions. The market for this segment in 2025 is estimated at $X,XXX million units.

- Dominant Country: United States, driven by advanced manufacturing, R&D, and strong end-user demand.

- Key Product Types: Styrenic Block Copolymer (TPE-S) and Thermoplastic Polyurethane (TPU) lead market growth.

- TPE-S: Estimated market volume in 2025: $X,XXX million units. Drivers: Versatile properties, applications in footwear, adhesives, consumer goods.

- TPU: Estimated market volume in 2025: $X,XXX million units. Drivers: High abrasion resistance, toughness, demand in automotive, medical.

- Dominant Applications:

- Automotive & Transportation: Estimated market size in 2025: $X,XXX million units. Drivers: Lightweighting, electrification, safety features.

- Building & Construction: Estimated market size in 2025: $X,XXX million units. Drivers: Durability, weather resistance for roofing, insulation, sealing.

- Growth Potential in Other Segments: Medical (biocompatibility requirements), Electricals & Electronics (insulation, sealing).

North America High-Performance Elastomers Industry Product Landscape

The North America High-Performance Elastomers market is characterized by continuous product innovation, focusing on enhanced performance metrics and expanded application ranges. Manufacturers are developing novel formulations that offer superior thermal stability, chemical resistance, UV resistance, and flame retardancy. For instance, advanced TPE-S grades are being engineered for improved oil and fuel resistance, crucial for automotive under-the-hood applications. New TPU formulations are emerging with bio-based content, catering to the growing demand for sustainable materials in consumer goods and footwear. Furthermore, the development of high-performance Thermoplastic Olefins (TPE-O) with improved impact strength and temperature resistance is broadening their use in demanding industrial applications. The ability to achieve precise material properties through sophisticated compounding techniques allows for tailor-made solutions that meet the stringent requirements of industries like aerospace and medical devices, highlighting the industry's commitment to pushing the boundaries of material science.

Key Drivers, Barriers & Challenges in North America High-Performance Elastomers Industry

Key Drivers:

- Technological Advancements: Innovations in material science leading to enhanced properties like superior thermal resistance, chemical inertness, and improved flexibility.

- Automotive Industry Demand: Increasing use of high-performance elastomers for lightweighting, fuel efficiency, and electrification of vehicles.

- Sustainability Initiatives: Growing preference for recyclable and bio-based elastomers, driving R&D in eco-friendly alternatives.

- Medical Device Sophistication: Demand for biocompatible, sterilizable, and high-performance materials in healthcare applications.

Barriers & Challenges:

- Raw Material Price Volatility: Fluctuations in the cost of petrochemical-based raw materials can impact production costs and profit margins.

- Stringent Regulatory Compliance: Evolving environmental and safety regulations may necessitate significant investment in product reformulation and process modification.

- Competition from Traditional Materials: Established thermoset elastomers and other materials can pose a competitive challenge in certain price-sensitive applications.

- Supply Chain Disruptions: Geopolitical events and global logistics challenges can impact the availability and timely delivery of raw materials and finished products.

- High Initial Investment: Developing and implementing advanced elastomer production technologies can require substantial capital expenditure.

Emerging Opportunities in North America High-Performance Elastomers Industry

Emerging opportunities in the North America High-Performance Elastomers market lie in the expanding adoption of these advanced materials in novel applications and geographies. The increasing focus on electric vehicles (EVs) presents a significant opportunity for specialized elastomers used in battery components, charging infrastructure, and thermal management systems. The medical sector continues to offer fertile ground, with a growing demand for advanced elastomers in prosthetics, implants, and drug delivery systems. Furthermore, the development of high-performance elastomers for renewable energy applications, such as solar panel components and wind turbine seals, represents an untapped market. The integration of smart functionalities into elastomer-based products, such as self-healing properties or embedded sensors, also signifies a promising area for future growth and differentiation.

Growth Accelerators in the North America High-Performance Elastomers Industry Industry

Several catalysts are propelling the long-term growth of the North America High-Performance Elastomers industry. Breakthroughs in polymerization processes, leading to more precise control over molecular architecture and enhanced material properties, are a significant accelerator. Strategic partnerships between material manufacturers, compounders, and end-users are fostering co-development and faster market penetration of innovative solutions. The increasing emphasis on circular economy principles and the development of advanced recycling technologies for thermoplastic elastomers will further boost their adoption by reducing environmental impact and enhancing cost-effectiveness. Government incentives and policies supporting green manufacturing and advanced materials development also play a crucial role in accelerating market expansion.

Key Players Shaping the North America High-Performance Elastomers Industry Market

- Mitsui Chemicals Inc

- Asahi Kasei Corporation

- Exxon Mobil Corporation

- KURARAY CO LTD

- Mitsubishi Chemical Corporation

- Evonik Industries AG

- LANXESS

- BASF SE

- Arkema Group

- Huntsman International LLC

- SABIC

- DuPont

- The Lubrizol Corporation

- KRATON CORPORATION

- Covestro AG

Notable Milestones in North America High-Performance Elastomers Industry Sector

- 2021 October: DuPont launched a new line of advanced TPEs for demanding automotive applications, enhancing thermal and chemical resistance.

- 2022 January: BASF SE announced significant investment in expanding its TPU production capacity in North America to meet growing demand.

- 2022 April: Covestro AG introduced a new bio-based thermoplastic polyurethane (TPU) for sustainable footwear solutions.

- 2023 March: Kraton Corporation completed the acquisition of a specialty elastomers producer, strengthening its portfolio in high-performance TPEs.

- 2023 August: ExxonMobil Chemical introduced advanced Styrenic Block Copolymer (TPE-S) grades with improved processing characteristics for consumer goods.

- 2024 February: Arkema Group unveiled innovative Elastomeric Alloy (TPE-V or TPV) solutions for the building and construction sector, offering enhanced weatherability.

In-Depth North America High-Performance Elastomers Industry Market Outlook

The future outlook for the North America High-Performance Elastomers market is exceptionally promising, driven by ongoing innovation and expanding applications. Growth accelerators such as advancements in sustainable material development, particularly bio-based and recyclable elastomers, will continue to shape market trends. Strategic collaborations between industry leaders and research institutions are expected to unlock new material functionalities and cost-effective production methods. The increasing demand from emerging sectors like renewable energy and advanced electronics, coupled with the sustained growth in traditional industries like automotive and healthcare, provides a robust foundation for future market expansion. The industry's ability to adapt to evolving regulatory landscapes and capitalize on the shift towards a circular economy will be crucial in realizing its full growth potential.

North America High-Performance Elastomers Industry Segmentation

-

1. Product Type

- 1.1. Styrenic Block Copolymer (TPE-S)

- 1.2. Thermoplastic Olefin (TPE-O)

- 1.3. Elastomeric Alloy (TPE-V or TPV)

- 1.4. Thermoplastic Polyurethane (TPU)

- 1.5. Thermoplastic Copolyester

- 1.6. Thermoplastic Polyamide

-

2. Application

- 2.1. Automotive & Transportation

- 2.2. Building & Construction

- 2.3. Footwear

- 2.4. Electricals & Electronics

- 2.5. Medical

- 2.6. Household Appliances

- 2.7. HVAC

- 2.8. Adhesive, Sealant & Coating

- 2.9. Other Applications

-

3. Geography

- 3.1. United States

- 3.2. Canada

- 3.3. Mexico

- 3.4. Rest of North America

North America High-Performance Elastomers Industry Segmentation By Geography

- 1. United States

- 2. Canada

- 3. Mexico

- 4. Rest of North America

North America High-Performance Elastomers Industry Regional Market Share

Geographic Coverage of North America High-Performance Elastomers Industry

North America High-Performance Elastomers Industry REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of > 3.50% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. ; Extensive Demand from the Automotive Industry; Growing Demand from Construction Industry

- 3.3. Market Restrains

- 3.3.1. ; Market Saturation in Applications

- 3.4. Market Trends

- 3.4.1. Increasing Usage in the Automotive and Transportation Applications

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. North America High-Performance Elastomers Industry Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Product Type

- 5.1.1. Styrenic Block Copolymer (TPE-S)

- 5.1.2. Thermoplastic Olefin (TPE-O)

- 5.1.3. Elastomeric Alloy (TPE-V or TPV)

- 5.1.4. Thermoplastic Polyurethane (TPU)

- 5.1.5. Thermoplastic Copolyester

- 5.1.6. Thermoplastic Polyamide

- 5.2. Market Analysis, Insights and Forecast - by Application

- 5.2.1. Automotive & Transportation

- 5.2.2. Building & Construction

- 5.2.3. Footwear

- 5.2.4. Electricals & Electronics

- 5.2.5. Medical

- 5.2.6. Household Appliances

- 5.2.7. HVAC

- 5.2.8. Adhesive, Sealant & Coating

- 5.2.9. Other Applications

- 5.3. Market Analysis, Insights and Forecast - by Geography

- 5.3.1. United States

- 5.3.2. Canada

- 5.3.3. Mexico

- 5.3.4. Rest of North America

- 5.4. Market Analysis, Insights and Forecast - by Region

- 5.4.1. United States

- 5.4.2. Canada

- 5.4.3. Mexico

- 5.4.4. Rest of North America

- 5.1. Market Analysis, Insights and Forecast - by Product Type

- 6. United States North America High-Performance Elastomers Industry Analysis, Insights and Forecast, 2020-2032

- 6.1. Market Analysis, Insights and Forecast - by Product Type

- 6.1.1. Styrenic Block Copolymer (TPE-S)

- 6.1.2. Thermoplastic Olefin (TPE-O)

- 6.1.3. Elastomeric Alloy (TPE-V or TPV)

- 6.1.4. Thermoplastic Polyurethane (TPU)

- 6.1.5. Thermoplastic Copolyester

- 6.1.6. Thermoplastic Polyamide

- 6.2. Market Analysis, Insights and Forecast - by Application

- 6.2.1. Automotive & Transportation

- 6.2.2. Building & Construction

- 6.2.3. Footwear

- 6.2.4. Electricals & Electronics

- 6.2.5. Medical

- 6.2.6. Household Appliances

- 6.2.7. HVAC

- 6.2.8. Adhesive, Sealant & Coating

- 6.2.9. Other Applications

- 6.3. Market Analysis, Insights and Forecast - by Geography

- 6.3.1. United States

- 6.3.2. Canada

- 6.3.3. Mexico

- 6.3.4. Rest of North America

- 6.1. Market Analysis, Insights and Forecast - by Product Type

- 7. Canada North America High-Performance Elastomers Industry Analysis, Insights and Forecast, 2020-2032

- 7.1. Market Analysis, Insights and Forecast - by Product Type

- 7.1.1. Styrenic Block Copolymer (TPE-S)

- 7.1.2. Thermoplastic Olefin (TPE-O)

- 7.1.3. Elastomeric Alloy (TPE-V or TPV)

- 7.1.4. Thermoplastic Polyurethane (TPU)

- 7.1.5. Thermoplastic Copolyester

- 7.1.6. Thermoplastic Polyamide

- 7.2. Market Analysis, Insights and Forecast - by Application

- 7.2.1. Automotive & Transportation

- 7.2.2. Building & Construction

- 7.2.3. Footwear

- 7.2.4. Electricals & Electronics

- 7.2.5. Medical

- 7.2.6. Household Appliances

- 7.2.7. HVAC

- 7.2.8. Adhesive, Sealant & Coating

- 7.2.9. Other Applications

- 7.3. Market Analysis, Insights and Forecast - by Geography

- 7.3.1. United States

- 7.3.2. Canada

- 7.3.3. Mexico

- 7.3.4. Rest of North America

- 7.1. Market Analysis, Insights and Forecast - by Product Type

- 8. Mexico North America High-Performance Elastomers Industry Analysis, Insights and Forecast, 2020-2032

- 8.1. Market Analysis, Insights and Forecast - by Product Type

- 8.1.1. Styrenic Block Copolymer (TPE-S)

- 8.1.2. Thermoplastic Olefin (TPE-O)

- 8.1.3. Elastomeric Alloy (TPE-V or TPV)

- 8.1.4. Thermoplastic Polyurethane (TPU)

- 8.1.5. Thermoplastic Copolyester

- 8.1.6. Thermoplastic Polyamide

- 8.2. Market Analysis, Insights and Forecast - by Application

- 8.2.1. Automotive & Transportation

- 8.2.2. Building & Construction

- 8.2.3. Footwear

- 8.2.4. Electricals & Electronics

- 8.2.5. Medical

- 8.2.6. Household Appliances

- 8.2.7. HVAC

- 8.2.8. Adhesive, Sealant & Coating

- 8.2.9. Other Applications

- 8.3. Market Analysis, Insights and Forecast - by Geography

- 8.3.1. United States

- 8.3.2. Canada

- 8.3.3. Mexico

- 8.3.4. Rest of North America

- 8.1. Market Analysis, Insights and Forecast - by Product Type

- 9. Rest of North America North America High-Performance Elastomers Industry Analysis, Insights and Forecast, 2020-2032

- 9.1. Market Analysis, Insights and Forecast - by Product Type

- 9.1.1. Styrenic Block Copolymer (TPE-S)

- 9.1.2. Thermoplastic Olefin (TPE-O)

- 9.1.3. Elastomeric Alloy (TPE-V or TPV)

- 9.1.4. Thermoplastic Polyurethane (TPU)

- 9.1.5. Thermoplastic Copolyester

- 9.1.6. Thermoplastic Polyamide

- 9.2. Market Analysis, Insights and Forecast - by Application

- 9.2.1. Automotive & Transportation

- 9.2.2. Building & Construction

- 9.2.3. Footwear

- 9.2.4. Electricals & Electronics

- 9.2.5. Medical

- 9.2.6. Household Appliances

- 9.2.7. HVAC

- 9.2.8. Adhesive, Sealant & Coating

- 9.2.9. Other Applications

- 9.3. Market Analysis, Insights and Forecast - by Geography

- 9.3.1. United States

- 9.3.2. Canada

- 9.3.3. Mexico

- 9.3.4. Rest of North America

- 9.1. Market Analysis, Insights and Forecast - by Product Type

- 10. Competitive Analysis

- 10.1. Market Share Analysis 2025

- 10.2. Company Profiles

- 10.2.1 Mitsui Chemicals Inc

- 10.2.1.1. Overview

- 10.2.1.2. Products

- 10.2.1.3. SWOT Analysis

- 10.2.1.4. Recent Developments

- 10.2.1.5. Financials (Based on Availability)

- 10.2.2 Asahi Kasei Corporation

- 10.2.2.1. Overview

- 10.2.2.2. Products

- 10.2.2.3. SWOT Analysis

- 10.2.2.4. Recent Developments

- 10.2.2.5. Financials (Based on Availability)

- 10.2.3 Exxon Mobil Corporation

- 10.2.3.1. Overview

- 10.2.3.2. Products

- 10.2.3.3. SWOT Analysis

- 10.2.3.4. Recent Developments

- 10.2.3.5. Financials (Based on Availability)

- 10.2.4 KURARAY CO LTD

- 10.2.4.1. Overview

- 10.2.4.2. Products

- 10.2.4.3. SWOT Analysis

- 10.2.4.4. Recent Developments

- 10.2.4.5. Financials (Based on Availability)

- 10.2.5 Mitsubishi Chemical Corporation

- 10.2.5.1. Overview

- 10.2.5.2. Products

- 10.2.5.3. SWOT Analysis

- 10.2.5.4. Recent Developments

- 10.2.5.5. Financials (Based on Availability)

- 10.2.6 Evonik Industries AG

- 10.2.6.1. Overview

- 10.2.6.2. Products

- 10.2.6.3. SWOT Analysis

- 10.2.6.4. Recent Developments

- 10.2.6.5. Financials (Based on Availability)

- 10.2.7 LANXESS

- 10.2.7.1. Overview

- 10.2.7.2. Products

- 10.2.7.3. SWOT Analysis

- 10.2.7.4. Recent Developments

- 10.2.7.5. Financials (Based on Availability)

- 10.2.8 BASF SE

- 10.2.8.1. Overview

- 10.2.8.2. Products

- 10.2.8.3. SWOT Analysis

- 10.2.8.4. Recent Developments

- 10.2.8.5. Financials (Based on Availability)

- 10.2.9 Arkema Group

- 10.2.9.1. Overview

- 10.2.9.2. Products

- 10.2.9.3. SWOT Analysis

- 10.2.9.4. Recent Developments

- 10.2.9.5. Financials (Based on Availability)

- 10.2.10 Huntsman International LLC

- 10.2.10.1. Overview

- 10.2.10.2. Products

- 10.2.10.3. SWOT Analysis

- 10.2.10.4. Recent Developments

- 10.2.10.5. Financials (Based on Availability)

- 10.2.11 SABIC

- 10.2.11.1. Overview

- 10.2.11.2. Products

- 10.2.11.3. SWOT Analysis

- 10.2.11.4. Recent Developments

- 10.2.11.5. Financials (Based on Availability)

- 10.2.12 DuPont

- 10.2.12.1. Overview

- 10.2.12.2. Products

- 10.2.12.3. SWOT Analysis

- 10.2.12.4. Recent Developments

- 10.2.12.5. Financials (Based on Availability)

- 10.2.13 The Lubrizol Corporation

- 10.2.13.1. Overview

- 10.2.13.2. Products

- 10.2.13.3. SWOT Analysis

- 10.2.13.4. Recent Developments

- 10.2.13.5. Financials (Based on Availability)

- 10.2.14 KRATON CORPORATION

- 10.2.14.1. Overview

- 10.2.14.2. Products

- 10.2.14.3. SWOT Analysis

- 10.2.14.4. Recent Developments

- 10.2.14.5. Financials (Based on Availability)

- 10.2.15 Covestro AG

- 10.2.15.1. Overview

- 10.2.15.2. Products

- 10.2.15.3. SWOT Analysis

- 10.2.15.4. Recent Developments

- 10.2.15.5. Financials (Based on Availability)

- 10.2.1 Mitsui Chemicals Inc

List of Figures

- Figure 1: North America High-Performance Elastomers Industry Revenue Breakdown (Million, %) by Product 2025 & 2033

- Figure 2: North America High-Performance Elastomers Industry Share (%) by Company 2025

List of Tables

- Table 1: North America High-Performance Elastomers Industry Revenue Million Forecast, by Product Type 2020 & 2033

- Table 2: North America High-Performance Elastomers Industry Volume K Tons Forecast, by Product Type 2020 & 2033

- Table 3: North America High-Performance Elastomers Industry Revenue Million Forecast, by Application 2020 & 2033

- Table 4: North America High-Performance Elastomers Industry Volume K Tons Forecast, by Application 2020 & 2033

- Table 5: North America High-Performance Elastomers Industry Revenue Million Forecast, by Geography 2020 & 2033

- Table 6: North America High-Performance Elastomers Industry Volume K Tons Forecast, by Geography 2020 & 2033

- Table 7: North America High-Performance Elastomers Industry Revenue Million Forecast, by Region 2020 & 2033

- Table 8: North America High-Performance Elastomers Industry Volume K Tons Forecast, by Region 2020 & 2033

- Table 9: North America High-Performance Elastomers Industry Revenue Million Forecast, by Product Type 2020 & 2033

- Table 10: North America High-Performance Elastomers Industry Volume K Tons Forecast, by Product Type 2020 & 2033

- Table 11: North America High-Performance Elastomers Industry Revenue Million Forecast, by Application 2020 & 2033

- Table 12: North America High-Performance Elastomers Industry Volume K Tons Forecast, by Application 2020 & 2033

- Table 13: North America High-Performance Elastomers Industry Revenue Million Forecast, by Geography 2020 & 2033

- Table 14: North America High-Performance Elastomers Industry Volume K Tons Forecast, by Geography 2020 & 2033

- Table 15: North America High-Performance Elastomers Industry Revenue Million Forecast, by Country 2020 & 2033

- Table 16: North America High-Performance Elastomers Industry Volume K Tons Forecast, by Country 2020 & 2033

- Table 17: North America High-Performance Elastomers Industry Revenue Million Forecast, by Product Type 2020 & 2033

- Table 18: North America High-Performance Elastomers Industry Volume K Tons Forecast, by Product Type 2020 & 2033

- Table 19: North America High-Performance Elastomers Industry Revenue Million Forecast, by Application 2020 & 2033

- Table 20: North America High-Performance Elastomers Industry Volume K Tons Forecast, by Application 2020 & 2033

- Table 21: North America High-Performance Elastomers Industry Revenue Million Forecast, by Geography 2020 & 2033

- Table 22: North America High-Performance Elastomers Industry Volume K Tons Forecast, by Geography 2020 & 2033

- Table 23: North America High-Performance Elastomers Industry Revenue Million Forecast, by Country 2020 & 2033

- Table 24: North America High-Performance Elastomers Industry Volume K Tons Forecast, by Country 2020 & 2033

- Table 25: North America High-Performance Elastomers Industry Revenue Million Forecast, by Product Type 2020 & 2033

- Table 26: North America High-Performance Elastomers Industry Volume K Tons Forecast, by Product Type 2020 & 2033

- Table 27: North America High-Performance Elastomers Industry Revenue Million Forecast, by Application 2020 & 2033

- Table 28: North America High-Performance Elastomers Industry Volume K Tons Forecast, by Application 2020 & 2033

- Table 29: North America High-Performance Elastomers Industry Revenue Million Forecast, by Geography 2020 & 2033

- Table 30: North America High-Performance Elastomers Industry Volume K Tons Forecast, by Geography 2020 & 2033

- Table 31: North America High-Performance Elastomers Industry Revenue Million Forecast, by Country 2020 & 2033

- Table 32: North America High-Performance Elastomers Industry Volume K Tons Forecast, by Country 2020 & 2033

- Table 33: North America High-Performance Elastomers Industry Revenue Million Forecast, by Product Type 2020 & 2033

- Table 34: North America High-Performance Elastomers Industry Volume K Tons Forecast, by Product Type 2020 & 2033

- Table 35: North America High-Performance Elastomers Industry Revenue Million Forecast, by Application 2020 & 2033

- Table 36: North America High-Performance Elastomers Industry Volume K Tons Forecast, by Application 2020 & 2033

- Table 37: North America High-Performance Elastomers Industry Revenue Million Forecast, by Geography 2020 & 2033

- Table 38: North America High-Performance Elastomers Industry Volume K Tons Forecast, by Geography 2020 & 2033

- Table 39: North America High-Performance Elastomers Industry Revenue Million Forecast, by Country 2020 & 2033

- Table 40: North America High-Performance Elastomers Industry Volume K Tons Forecast, by Country 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the North America High-Performance Elastomers Industry?

The projected CAGR is approximately > 3.50%.

2. Which companies are prominent players in the North America High-Performance Elastomers Industry?

Key companies in the market include Mitsui Chemicals Inc, Asahi Kasei Corporation, Exxon Mobil Corporation, KURARAY CO LTD, Mitsubishi Chemical Corporation, Evonik Industries AG, LANXESS, BASF SE, Arkema Group, Huntsman International LLC, SABIC, DuPont, The Lubrizol Corporation, KRATON CORPORATION, Covestro AG.

3. What are the main segments of the North America High-Performance Elastomers Industry?

The market segments include Product Type, Application, Geography.

4. Can you provide details about the market size?

The market size is estimated to be USD XX Million as of 2022.

5. What are some drivers contributing to market growth?

; Extensive Demand from the Automotive Industry; Growing Demand from Construction Industry.

6. What are the notable trends driving market growth?

Increasing Usage in the Automotive and Transportation Applications.

7. Are there any restraints impacting market growth?

; Market Saturation in Applications.

8. Can you provide examples of recent developments in the market?

N/A

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4750, USD 5250, and USD 8750 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in Million and volume, measured in K Tons.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "North America High-Performance Elastomers Industry," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the North America High-Performance Elastomers Industry report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the North America High-Performance Elastomers Industry?

To stay informed about further developments, trends, and reports in the North America High-Performance Elastomers Industry, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

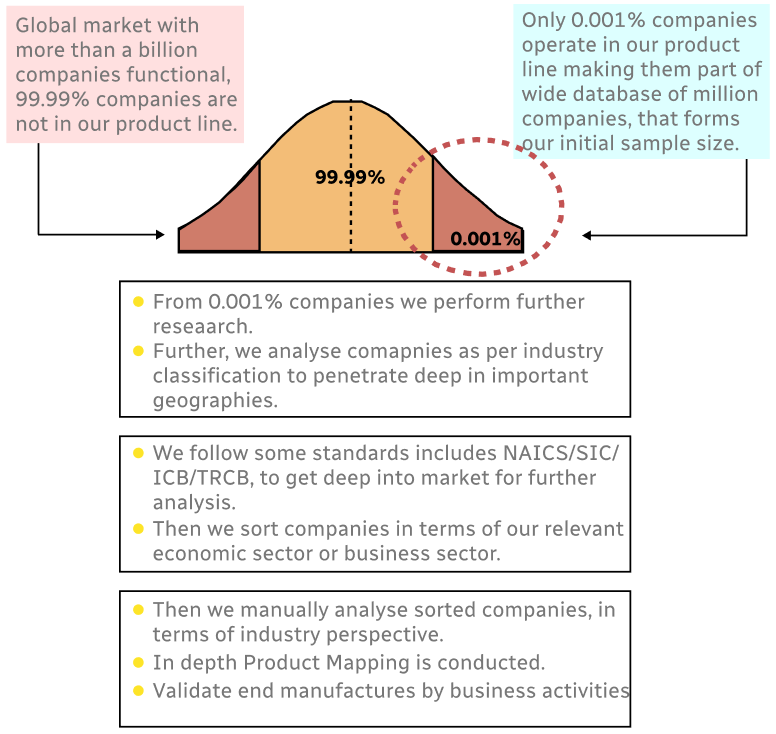

Step 1 - Identification of Relevant Samples Size from Population Database

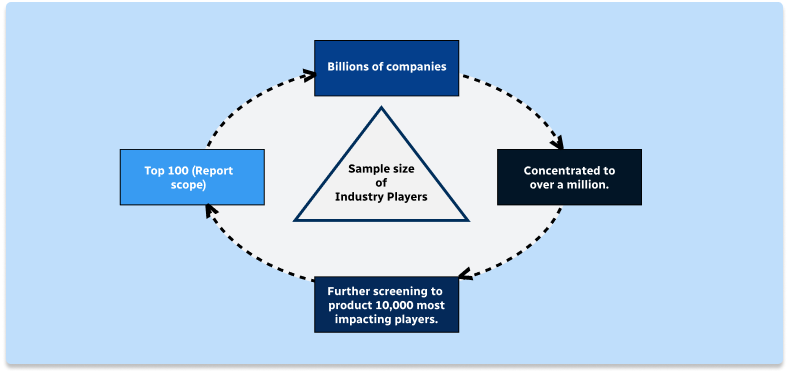

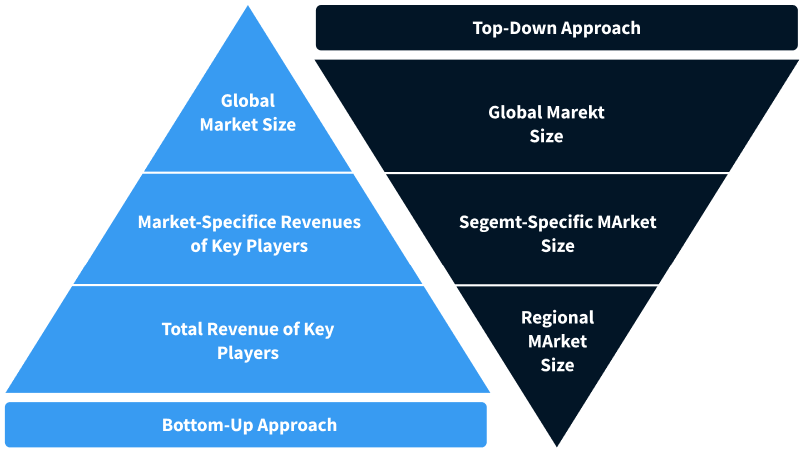

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

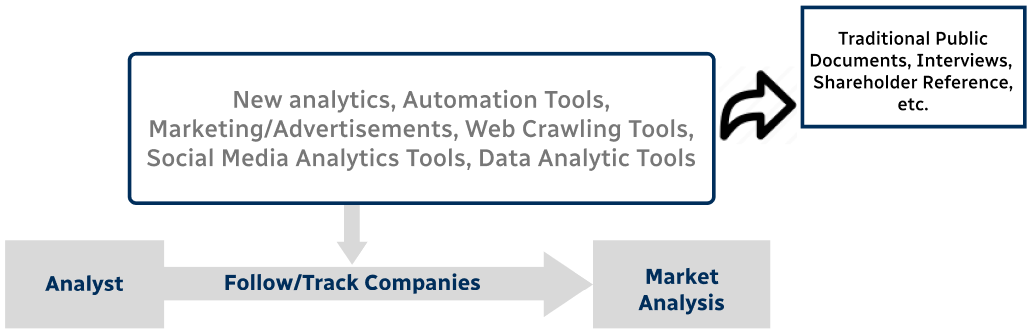

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence