Key Insights

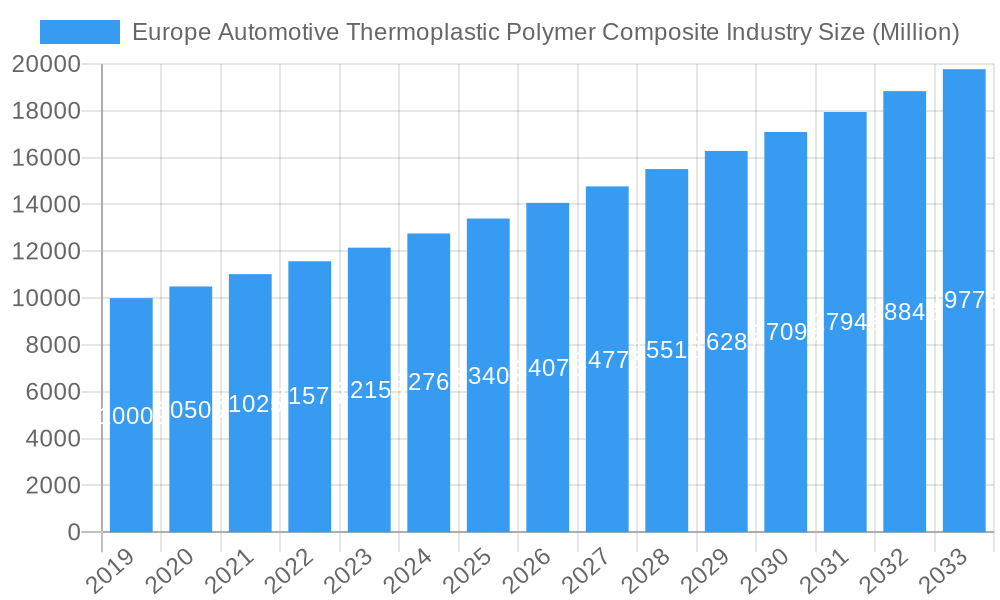

The Europe Automotive Thermoplastic Polymer Composite Industry is poised for robust expansion, projected to reach a market size of approximately USD 15,000 million by 2025, with a compelling Compound Annual Growth Rate (CAGR) exceeding 6.00% through 2033. This growth is significantly driven by the automotive sector's relentless pursuit of lightweighting solutions to enhance fuel efficiency, reduce emissions, and improve overall vehicle performance. The increasing adoption of advanced manufacturing techniques such as Resin Transfer Molding (RTM) and Vacuum Infusion Processing (VIP) is further fueling this expansion, enabling the production of complex, high-strength components with greater precision and efficiency. Thermoplastic composites, with their inherent recyclability and faster processing times compared to thermosets, are becoming the material of choice for a wide array of automotive applications, including structural assemblies, powertrain components, and interior and exterior elements. The industry's focus on sustainability and regulatory pressures to meet stringent environmental standards are acting as powerful catalysts for the wider adoption of these advanced materials.

Europe Automotive Thermoplastic Polymer Composite Industry Market Size (In Billion)

Key trends shaping the market include the growing demand for high-performance composites that can withstand extreme temperatures and mechanical stresses, alongside advancements in material science leading to the development of novel thermoplastic resins and reinforcing fibers. The ongoing electrification of vehicles also presents a significant opportunity, with thermoplastic composites being ideal for battery enclosures, charging infrastructure, and lightweight structural components that are crucial for extending EV range. However, certain restraints, such as the initial high cost of raw materials and specialized manufacturing equipment, alongside the need for extensive consumer and industry education regarding the benefits and handling of these advanced materials, require strategic attention. Leading companies like DuPont de Nemours, Daicel Polymer Ltd., and Arkema Group are actively investing in research and development to innovate and expand their product portfolios, catering to the evolving demands of automotive manufacturers across Europe, with a particular focus on Germany, France, and the United Kingdom, which are expected to dominate regional market share.

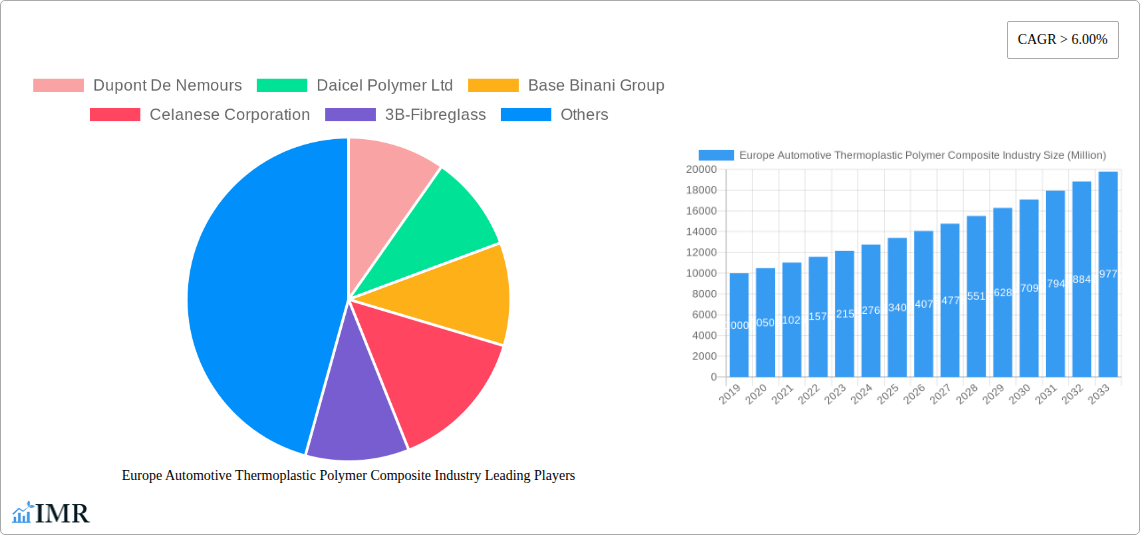

Europe Automotive Thermoplastic Polymer Composite Industry Company Market Share

Europe Automotive Thermoplastic Polymer Composite Industry Market Dynamics & Structure

The Europe Automotive Thermoplastic Polymer Composite Industry is characterized by a moderately concentrated market, with leading players such as Dupont De Nemours, Daicel Polymer Ltd, Celanese Corporation, and Arkema Group holding significant market shares. Technological innovation is a primary driver, fueled by the continuous demand for lightweight materials to meet stringent CO2 emission regulations and enhance fuel efficiency. The regulatory framework, particularly EU directives on vehicle weight reduction and sustainability, is a critical influence shaping market dynamics. Competitive product substitutes include traditional metals like aluminum and steel, as well as other advanced composite materials. End-user demographics are shifting towards a greater demand for electric vehicles (EVs) and hybrid models, which inherently require lighter components. Mergers and Acquisitions (M&A) activity is on the rise as key players seek to consolidate their market position, expand their product portfolios, and secure raw material supply chains.

- Market Concentration: Dominated by a few key players, with a growing trend towards consolidation.

- Technological Innovation: Driven by lightweighting, sustainability, and performance enhancement.

- Regulatory Framework: Stringent emission standards and recyclability mandates heavily influence material choices.

- Competitive Substitutes: Traditional metals (aluminum, steel), thermoset composites, and advanced polymers.

- End-User Demographics: Increasing demand for EVs and hybrids driving lightweighting requirements.

- M&A Trends: Strategic acquisitions to gain market share, enhance capabilities, and expand product offerings.

Europe Automotive Thermoplastic Polymer Composite Industry Growth Trends & Insights

The Europe Automotive Thermoplastic Polymer Composite Industry is poised for robust growth, driven by a confluence of factors aimed at enhancing vehicle performance, safety, and sustainability. The market size is projected to expand significantly, fueled by increasing adoption rates of thermoplastic composites across various automotive applications. This trend is underpinned by their inherent advantages, including superior strength-to-weight ratios, design flexibility, and recyclability compared to traditional materials. Technological disruptions, such as advancements in polymer chemistry, reinforcement technologies, and manufacturing processes, are further accelerating this adoption. For instance, the development of high-performance thermoplastics like PEEK and PPS, coupled with advanced fiber reinforcements like carbon fiber and glass fiber, enables the creation of components that are both lighter and stronger.

Consumer behavior shifts, particularly the growing environmental consciousness and the increasing demand for fuel-efficient and electric vehicles, are acting as powerful catalysts. Automakers are actively seeking material solutions that reduce overall vehicle weight, thereby improving energy efficiency and extending the range of EVs. This push for lightweighting is not limited to structural components but extends to interior and exterior applications, as well as powertrain elements. The ability of thermoplastic composites to be molded into complex shapes also offers designers greater freedom, leading to integrated components that reduce assembly time and costs. Furthermore, the inherent recyclability of thermoplastics aligns with the circular economy principles increasingly prioritized by both regulators and consumers. The overall CAGR is estimated to be xx% during the forecast period, indicating a substantial upward trajectory. Market penetration is expected to reach xx% of the total automotive material market by 2033, demonstrating a significant shift away from conventional materials.

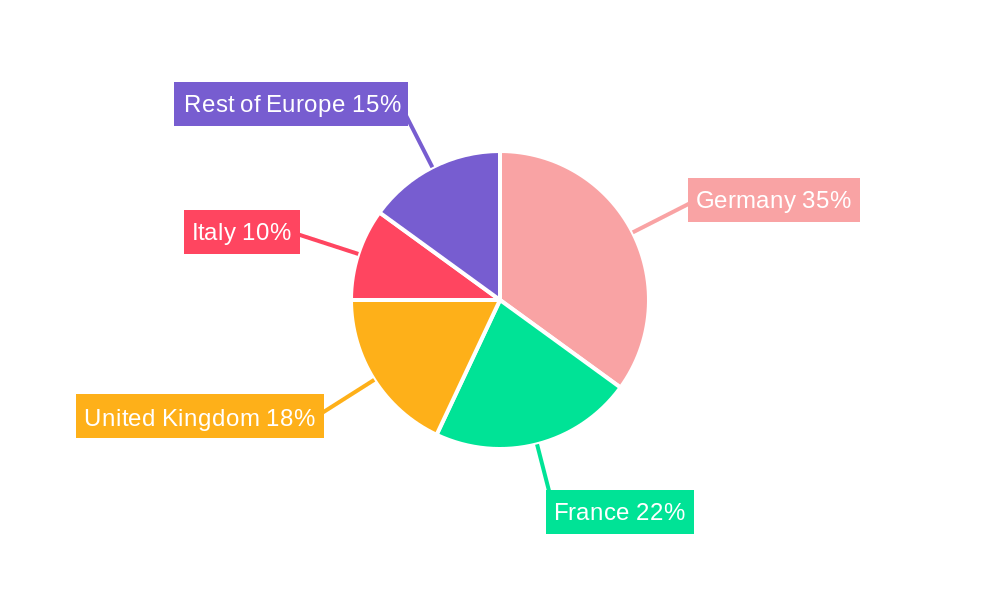

Dominant Regions, Countries, or Segments in Europe Automotive Thermoplastic Polymer Composite Industry

The Injection Molding production type segment is a significant driver of growth within the Europe Automotive Thermoplastic Polymer Composite Industry. Its dominance is attributed to the inherent efficiency and scalability of the injection molding process, making it ideal for mass production of complex automotive components. This method allows for precise control over part geometry and thickness, facilitating the integration of multiple functionalities into single parts, thereby reducing assembly requirements. Coupled with the widespread availability of advanced thermoplastic resins and reinforcing fibers, injection molding offers a compelling solution for high-volume manufacturing needs.

Within the application types, Structural Assembly applications are experiencing exceptional growth. This is directly linked to the automotive industry's relentless pursuit of lightweighting to meet stringent emission standards and improve fuel efficiency, especially for electric vehicles. Thermoplastic composites offer a superior strength-to-weight ratio compared to traditional metals, making them indispensable for critical structural components. The ability to design and produce integrated structural parts using injection molding further enhances weight reduction and assembly simplification. Economic policies promoting sustainable manufacturing and incentives for adopting lightweight materials are bolstering this trend. For example, Germany, with its strong automotive manufacturing base and advanced research and development capabilities, leads in the adoption and innovation of these materials for structural applications.

- Dominant Production Type: Injection Molding, owing to its efficiency, scalability, and ability to produce complex parts.

- Dominant Application Type: Structural Assembly, driven by the critical need for lightweighting in modern vehicles.

- Key Growth Drivers in Germany: Strong automotive OEM presence, advanced R&D infrastructure, and supportive government policies for lightweight materials and EVs.

- Market Share: Injection molding for structural assembly applications is estimated to hold xx% of the total market share in 2025.

- Growth Potential: Significant growth potential due to continued focus on vehicle electrification and stringent emission regulations.

- Technological Advancements: Continuous innovation in mold design, fiber placement, and material compounding for injection molding processes.

Europe Automotive Thermoplastic Polymer Composite Industry Product Landscape

The Europe Automotive Thermoplastic Polymer Composite Industry is witnessing a surge in product innovations centered on enhancing performance, durability, and sustainability. Manufacturers are developing advanced thermoplastic composites with tailored properties, such as high impact resistance, excellent thermal stability, and improved flame retardancy, to meet the demanding requirements of automotive applications. Carbon fiber reinforced thermoplastics (CFRTPs) are gaining prominence for their exceptional strength and stiffness, enabling the production of lightweight structural components and body panels. Glass fiber reinforced thermoplastics (GFRTPs) offer a cost-effective alternative for interior and exterior parts. Unique selling propositions include the ability to achieve intricate designs, reduce part count through integration, and offer faster processing cycles compared to thermosets. Technological advancements in polymer matrices, such as long fiber thermoplastics (LFTs) and continuous fiber thermoplastics (CFTs), are further expanding the application scope and performance capabilities of these materials.

Key Drivers, Barriers & Challenges in Europe Automotive Thermoplastic Polymer Composite Industry

Key Drivers:

- Stringent Emission Regulations: Driving the demand for lightweight materials to reduce vehicle weight and improve fuel efficiency, particularly for electric vehicles (EVs).

- Technological Advancements: Continuous innovation in composite materials and manufacturing processes enabling higher performance and cost-effectiveness.

- Growing EV Market: The increasing popularity of EVs necessitates lighter components to maximize range and performance.

- Sustainability Initiatives: The inherent recyclability of thermoplastics aligns with circular economy goals and growing consumer demand for eco-friendly products.

Barriers & Challenges:

- High Initial Investment: The cost of advanced manufacturing equipment and tooling for thermoplastic composites can be substantial.

- Material Costs: While declining, the cost of high-performance thermoplastic resins and advanced fibers can still be higher than traditional materials.

- Supply Chain Complexity: Ensuring a consistent and reliable supply of specialized raw materials can be a challenge.

- Recycling Infrastructure Development: While recyclable, establishing robust and scalable recycling streams for automotive thermoplastic composites is an ongoing process.

- Skilled Labor Shortage: A lack of trained personnel in advanced composite manufacturing techniques can hinder adoption.

Emerging Opportunities in Europe Automotive Thermoplastic Polymer Composite Industry

Emerging opportunities lie in the development of next-generation thermoplastic composites with enhanced functionalities, such as self-healing properties or integrated sensor capabilities, for advanced driver-assistance systems (ADAS). The increasing focus on electric vehicle battery enclosures presents a significant growth area, requiring lightweight, strong, and fire-resistant materials. Furthermore, the development of bio-based and recycled thermoplastic composites offers a pathway to address sustainability concerns and tap into the growing demand for eco-friendly automotive solutions. The expansion of multi-material design approaches, where thermoplastic composites are strategically integrated with other materials to optimize performance and cost, also presents considerable potential.

Growth Accelerators in the Europe Automotive Thermoplastic Polymer Composite Industry Industry

Several catalysts are accelerating the long-term growth of the Europe Automotive Thermoplastic Polymer Composite Industry. Breakthroughs in polymer science leading to materials with even higher performance-to-weight ratios are a key accelerator. Strategic partnerships between material suppliers, compounders, and automotive OEMs are fostering innovation and accelerating the adoption of new solutions. Market expansion strategies focusing on emerging applications beyond traditional structural components, such as advanced thermal management systems and aerodynamic elements, are also driving growth. The increasing emphasis on digitalization and automation in manufacturing processes for thermoplastic composites is improving efficiency and reducing production costs, further enhancing their competitiveness.

Key Players Shaping the Europe Automotive Thermoplastic Polymer Composite Industry Market

- Dupont De Nemours

- Daicel Polymer Ltd

- Base Binani Group

- Celanese Corporation

- 3B-Fibreglass

- Arkema Group

- Technocompound GmbH

- Polyone Corporation

- Hexcel Corporation

- Cytec Industries Inc

Notable Milestones in Europe Automotive Thermoplastic Polymer Composite Industry Sector

- 2019: Launch of advanced long fiber thermoplastic (LFT) grades by leading compounders, enabling higher strength and stiffness for structural components.

- 2020: Increased investment in R&D for recyclable thermoplastic composites in response to evolving EU regulations on end-of-life vehicle management.

- 2021: Major automotive OEMs announcing targets for increased use of lightweight composite materials in new vehicle platforms.

- 2022: Development of novel thermoplastic composite solutions for electric vehicle battery pack components, focusing on safety and thermal management.

- 2023: Significant advancements in overmolding technologies for thermoplastic composites, allowing for greater design freedom and component integration.

- 2024: Growing M&A activity as companies seek to strengthen their position in the rapidly expanding lightweight materials market.

In-Depth Europe Automotive Thermoplastic Polymer Composite Industry Market Outlook

The outlook for the Europe Automotive Thermoplastic Polymer Composite Industry remains exceptionally bright, driven by the ongoing electrification of the automotive sector and the persistent global push for enhanced fuel efficiency and reduced emissions. Key growth accelerators include continuous advancements in material science leading to higher performance and lower costs, coupled with the strategic expansion of applications into new automotive sub-systems. The increasing integration of thermoplastic composites in electric vehicle battery systems and lightweight structural components will underpin substantial market expansion. Furthermore, the growing emphasis on circular economy principles and the development of more sustainable composite solutions will unlock new avenues for growth and innovation, ensuring a dynamic and evolving market landscape.

Europe Automotive Thermoplastic Polymer Composite Industry Segmentation

-

1. Production Type

- 1.1. Hand Layup

- 1.2. Resin Transfer Molding

- 1.3. Vaccum Infusion Processing

- 1.4. Compression Molding

- 1.5. Injection Molding

-

2. Application Type

- 2.1. Structural Assembly

- 2.2. Power Train Components

- 2.3. Interior

- 2.4. Exterior

- 2.5. Others

Europe Automotive Thermoplastic Polymer Composite Industry Segmentation By Geography

- 1. Germay

- 2. France

- 3. United Kingdom

- 4. Italy

- 5. Rest of Europe

Europe Automotive Thermoplastic Polymer Composite Industry Regional Market Share

Geographic Coverage of Europe Automotive Thermoplastic Polymer Composite Industry

Europe Automotive Thermoplastic Polymer Composite Industry REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 12% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. Growing Demand for Lightweight Materials

- 3.3. Market Restrains

- 3.3.1. High Expenses of Composite Processing and Manufacturing

- 3.4. Market Trends

- 3.4.1. Glass Mat Thermoplastic (GMT) is Expected to Grow with a Fast Pace

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Europe Automotive Thermoplastic Polymer Composite Industry Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Production Type

- 5.1.1. Hand Layup

- 5.1.2. Resin Transfer Molding

- 5.1.3. Vaccum Infusion Processing

- 5.1.4. Compression Molding

- 5.1.5. Injection Molding

- 5.2. Market Analysis, Insights and Forecast - by Application Type

- 5.2.1. Structural Assembly

- 5.2.2. Power Train Components

- 5.2.3. Interior

- 5.2.4. Exterior

- 5.2.5. Others

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. Germay

- 5.3.2. France

- 5.3.3. United Kingdom

- 5.3.4. Italy

- 5.3.5. Rest of Europe

- 5.1. Market Analysis, Insights and Forecast - by Production Type

- 6. Germay Europe Automotive Thermoplastic Polymer Composite Industry Analysis, Insights and Forecast, 2020-2032

- 6.1. Market Analysis, Insights and Forecast - by Production Type

- 6.1.1. Hand Layup

- 6.1.2. Resin Transfer Molding

- 6.1.3. Vaccum Infusion Processing

- 6.1.4. Compression Molding

- 6.1.5. Injection Molding

- 6.2. Market Analysis, Insights and Forecast - by Application Type

- 6.2.1. Structural Assembly

- 6.2.2. Power Train Components

- 6.2.3. Interior

- 6.2.4. Exterior

- 6.2.5. Others

- 6.1. Market Analysis, Insights and Forecast - by Production Type

- 7. France Europe Automotive Thermoplastic Polymer Composite Industry Analysis, Insights and Forecast, 2020-2032

- 7.1. Market Analysis, Insights and Forecast - by Production Type

- 7.1.1. Hand Layup

- 7.1.2. Resin Transfer Molding

- 7.1.3. Vaccum Infusion Processing

- 7.1.4. Compression Molding

- 7.1.5. Injection Molding

- 7.2. Market Analysis, Insights and Forecast - by Application Type

- 7.2.1. Structural Assembly

- 7.2.2. Power Train Components

- 7.2.3. Interior

- 7.2.4. Exterior

- 7.2.5. Others

- 7.1. Market Analysis, Insights and Forecast - by Production Type

- 8. United Kingdom Europe Automotive Thermoplastic Polymer Composite Industry Analysis, Insights and Forecast, 2020-2032

- 8.1. Market Analysis, Insights and Forecast - by Production Type

- 8.1.1. Hand Layup

- 8.1.2. Resin Transfer Molding

- 8.1.3. Vaccum Infusion Processing

- 8.1.4. Compression Molding

- 8.1.5. Injection Molding

- 8.2. Market Analysis, Insights and Forecast - by Application Type

- 8.2.1. Structural Assembly

- 8.2.2. Power Train Components

- 8.2.3. Interior

- 8.2.4. Exterior

- 8.2.5. Others

- 8.1. Market Analysis, Insights and Forecast - by Production Type

- 9. Italy Europe Automotive Thermoplastic Polymer Composite Industry Analysis, Insights and Forecast, 2020-2032

- 9.1. Market Analysis, Insights and Forecast - by Production Type

- 9.1.1. Hand Layup

- 9.1.2. Resin Transfer Molding

- 9.1.3. Vaccum Infusion Processing

- 9.1.4. Compression Molding

- 9.1.5. Injection Molding

- 9.2. Market Analysis, Insights and Forecast - by Application Type

- 9.2.1. Structural Assembly

- 9.2.2. Power Train Components

- 9.2.3. Interior

- 9.2.4. Exterior

- 9.2.5. Others

- 9.1. Market Analysis, Insights and Forecast - by Production Type

- 10. Rest of Europe Europe Automotive Thermoplastic Polymer Composite Industry Analysis, Insights and Forecast, 2020-2032

- 10.1. Market Analysis, Insights and Forecast - by Production Type

- 10.1.1. Hand Layup

- 10.1.2. Resin Transfer Molding

- 10.1.3. Vaccum Infusion Processing

- 10.1.4. Compression Molding

- 10.1.5. Injection Molding

- 10.2. Market Analysis, Insights and Forecast - by Application Type

- 10.2.1. Structural Assembly

- 10.2.2. Power Train Components

- 10.2.3. Interior

- 10.2.4. Exterior

- 10.2.5. Others

- 10.1. Market Analysis, Insights and Forecast - by Production Type

- 11. Competitive Analysis

- 11.1. Market Share Analysis 2025

- 11.2. Company Profiles

- 11.2.1 Dupont De Nemours

- 11.2.1.1. Overview

- 11.2.1.2. Products

- 11.2.1.3. SWOT Analysis

- 11.2.1.4. Recent Developments

- 11.2.1.5. Financials (Based on Availability)

- 11.2.2 Daicel Polymer Ltd

- 11.2.2.1. Overview

- 11.2.2.2. Products

- 11.2.2.3. SWOT Analysis

- 11.2.2.4. Recent Developments

- 11.2.2.5. Financials (Based on Availability)

- 11.2.3 Base Binani Group

- 11.2.3.1. Overview

- 11.2.3.2. Products

- 11.2.3.3. SWOT Analysis

- 11.2.3.4. Recent Developments

- 11.2.3.5. Financials (Based on Availability)

- 11.2.4 Celanese Corporation

- 11.2.4.1. Overview

- 11.2.4.2. Products

- 11.2.4.3. SWOT Analysis

- 11.2.4.4. Recent Developments

- 11.2.4.5. Financials (Based on Availability)

- 11.2.5 3B-Fibreglass

- 11.2.5.1. Overview

- 11.2.5.2. Products

- 11.2.5.3. SWOT Analysis

- 11.2.5.4. Recent Developments

- 11.2.5.5. Financials (Based on Availability)

- 11.2.6 Arkema Group

- 11.2.6.1. Overview

- 11.2.6.2. Products

- 11.2.6.3. SWOT Analysis

- 11.2.6.4. Recent Developments

- 11.2.6.5. Financials (Based on Availability)

- 11.2.7 Technocompound GmbH

- 11.2.7.1. Overview

- 11.2.7.2. Products

- 11.2.7.3. SWOT Analysis

- 11.2.7.4. Recent Developments

- 11.2.7.5. Financials (Based on Availability)

- 11.2.8 Polyone Corporatio

- 11.2.8.1. Overview

- 11.2.8.2. Products

- 11.2.8.3. SWOT Analysis

- 11.2.8.4. Recent Developments

- 11.2.8.5. Financials (Based on Availability)

- 11.2.9 Hexcel Corporation

- 11.2.9.1. Overview

- 11.2.9.2. Products

- 11.2.9.3. SWOT Analysis

- 11.2.9.4. Recent Developments

- 11.2.9.5. Financials (Based on Availability)

- 11.2.10 Cytec Industries Inc

- 11.2.10.1. Overview

- 11.2.10.2. Products

- 11.2.10.3. SWOT Analysis

- 11.2.10.4. Recent Developments

- 11.2.10.5. Financials (Based on Availability)

- 11.2.1 Dupont De Nemours

List of Figures

- Figure 1: Europe Automotive Thermoplastic Polymer Composite Industry Revenue Breakdown (undefined, %) by Product 2025 & 2033

- Figure 2: Europe Automotive Thermoplastic Polymer Composite Industry Share (%) by Company 2025

List of Tables

- Table 1: Europe Automotive Thermoplastic Polymer Composite Industry Revenue undefined Forecast, by Production Type 2020 & 2033

- Table 2: Europe Automotive Thermoplastic Polymer Composite Industry Revenue undefined Forecast, by Application Type 2020 & 2033

- Table 3: Europe Automotive Thermoplastic Polymer Composite Industry Revenue undefined Forecast, by Region 2020 & 2033

- Table 4: Europe Automotive Thermoplastic Polymer Composite Industry Revenue undefined Forecast, by Production Type 2020 & 2033

- Table 5: Europe Automotive Thermoplastic Polymer Composite Industry Revenue undefined Forecast, by Application Type 2020 & 2033

- Table 6: Europe Automotive Thermoplastic Polymer Composite Industry Revenue undefined Forecast, by Country 2020 & 2033

- Table 7: Europe Automotive Thermoplastic Polymer Composite Industry Revenue undefined Forecast, by Production Type 2020 & 2033

- Table 8: Europe Automotive Thermoplastic Polymer Composite Industry Revenue undefined Forecast, by Application Type 2020 & 2033

- Table 9: Europe Automotive Thermoplastic Polymer Composite Industry Revenue undefined Forecast, by Country 2020 & 2033

- Table 10: Europe Automotive Thermoplastic Polymer Composite Industry Revenue undefined Forecast, by Production Type 2020 & 2033

- Table 11: Europe Automotive Thermoplastic Polymer Composite Industry Revenue undefined Forecast, by Application Type 2020 & 2033

- Table 12: Europe Automotive Thermoplastic Polymer Composite Industry Revenue undefined Forecast, by Country 2020 & 2033

- Table 13: Europe Automotive Thermoplastic Polymer Composite Industry Revenue undefined Forecast, by Production Type 2020 & 2033

- Table 14: Europe Automotive Thermoplastic Polymer Composite Industry Revenue undefined Forecast, by Application Type 2020 & 2033

- Table 15: Europe Automotive Thermoplastic Polymer Composite Industry Revenue undefined Forecast, by Country 2020 & 2033

- Table 16: Europe Automotive Thermoplastic Polymer Composite Industry Revenue undefined Forecast, by Production Type 2020 & 2033

- Table 17: Europe Automotive Thermoplastic Polymer Composite Industry Revenue undefined Forecast, by Application Type 2020 & 2033

- Table 18: Europe Automotive Thermoplastic Polymer Composite Industry Revenue undefined Forecast, by Country 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Europe Automotive Thermoplastic Polymer Composite Industry?

The projected CAGR is approximately 12%.

2. Which companies are prominent players in the Europe Automotive Thermoplastic Polymer Composite Industry?

Key companies in the market include Dupont De Nemours, Daicel Polymer Ltd, Base Binani Group, Celanese Corporation, 3B-Fibreglass, Arkema Group, Technocompound GmbH, Polyone Corporatio, Hexcel Corporation, Cytec Industries Inc.

3. What are the main segments of the Europe Automotive Thermoplastic Polymer Composite Industry?

The market segments include Production Type, Application Type.

4. Can you provide details about the market size?

The market size is estimated to be USD XXX N/A as of 2022.

5. What are some drivers contributing to market growth?

Growing Demand for Lightweight Materials.

6. What are the notable trends driving market growth?

Glass Mat Thermoplastic (GMT) is Expected to Grow with a Fast Pace.

7. Are there any restraints impacting market growth?

High Expenses of Composite Processing and Manufacturing.

8. Can you provide examples of recent developments in the market?

N/A

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4750, USD 4950, and USD 6800 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in N/A.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Europe Automotive Thermoplastic Polymer Composite Industry," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Europe Automotive Thermoplastic Polymer Composite Industry report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Europe Automotive Thermoplastic Polymer Composite Industry?

To stay informed about further developments, trends, and reports in the Europe Automotive Thermoplastic Polymer Composite Industry, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

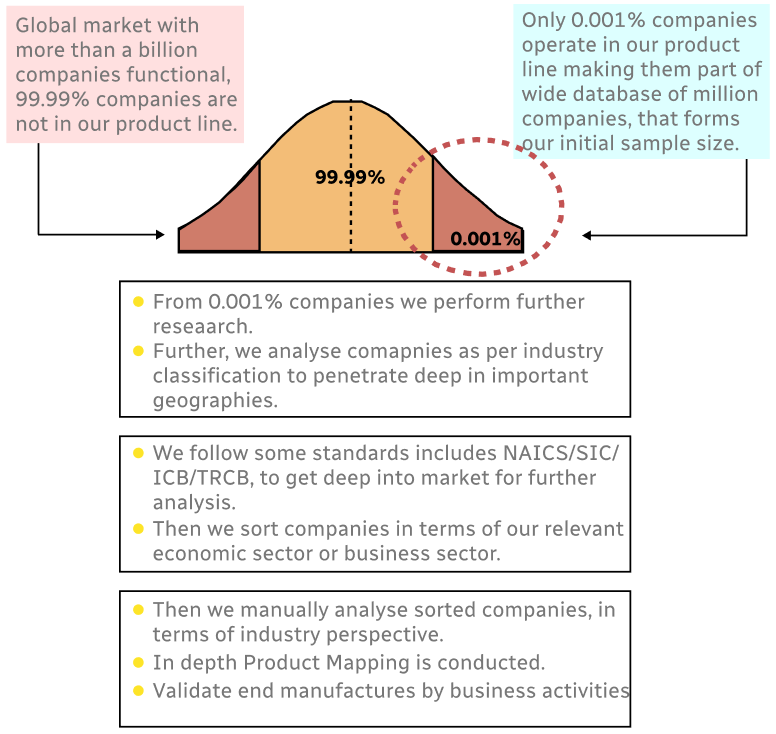

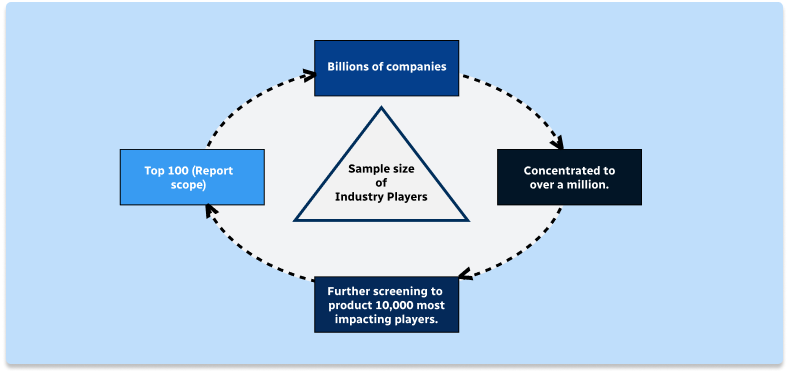

Step 1 - Identification of Relevant Samples Size from Population Database

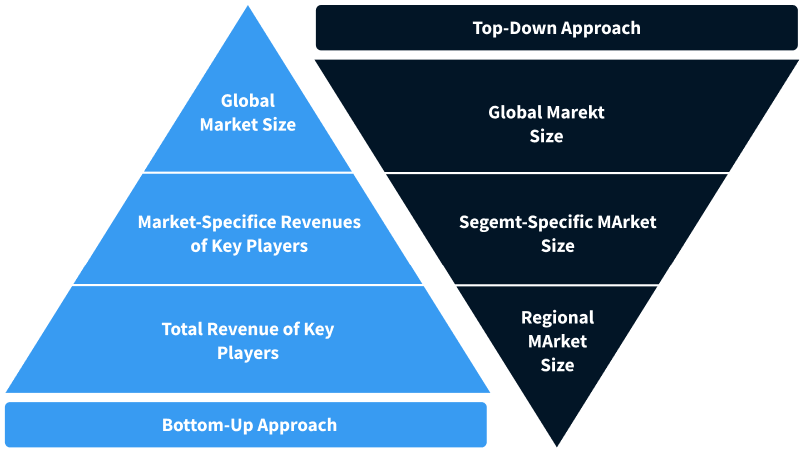

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

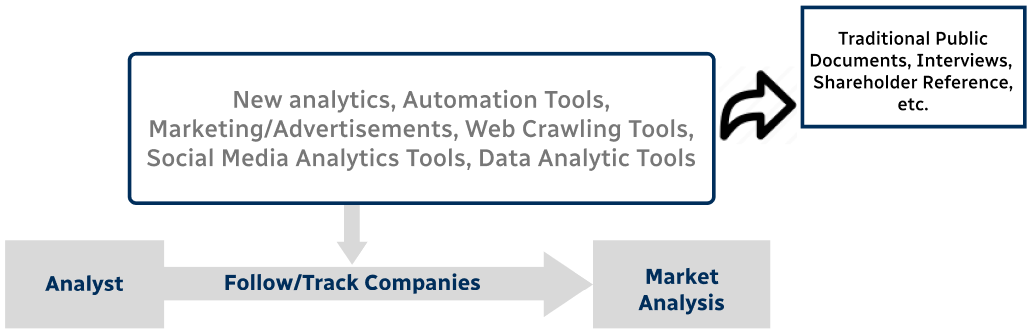

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence